SV Belle and Beast

Building a Sailboat Trailer

Since Belle did not come with a trailer, much of why she was so inexpensive, we had to source a trailer to put under her to make her useful to us. Buying a custom trailer was going to be in the $3000 range, 10X what we paid for Belle. Adapting a used trailer was going to be the only affordable. So this is how we set about building a sailboat trailer.

So how does one go about building a sailboat trailer? The easy way is to start with an existing trailer. We need some fairly detailed knowledge about the boat we intend to trailer. We need a trailer that is long enough and strong enough to support the load so we need to know where the center of gravity of the boat is, how far forward and aft the bow and stern are from this point, how much the boat weighs, how far from centerline the reasonably flat/horizontal hull areas extend, and how far these areas are vertically from the bottom of the keel.

Measure It Up

When building a trailer for a sailboat, getting sizes and dimensions right is crucial. I took some critical dimensions during my survey of the boat (yes, I felt comfortable doing my own survey) and while shopping for the trailer. You can see those above. I used these to source my parts for the trailer refit. Our sailboat, an O’Day 23-2 comes in at a max displacement of about 3500lbs. That is equal to the maximum weight of the boat. So I knew I had to find a trailer that could hold 3500lbs. I also knew the shoal keel was going to cause the boat to trailer rather high off the ground and from my father’s experiences I knew I wanted the boat as low as possible and as long a tongue as possible to give us the most flexibility in launch ramp choices. The higher your boat sits on the trailer, the deeper and steeper the ramp you are going to need to launch and recover the boat.

We located our trailer at KM Boat Salvage in Plaistow, NH. Keith had about 30 trailers to choose from. While there were some tandem axle trailers suitable, I decided to go with a heavy single axle Escort brand trailer for a few reasons.

- A single axle is more maneuverable, less tire drag in tight turns.

- This trailer was all galvanized and had hydraulic surge brakes (working or not?)

- The price was half that of the tandem axle trailers ($650)

Looking at the wheels/hubs, I could see they were 6 lugs with 2.5″ caps. And counting the leaf springs, I could see there were 5 leaves. This suggests fairly clearly that the trailer has a ~5000lb class axle. That gives us plenty of room for the weight of the trailer itself once we subtract the weight of the boat. (1500lbs allowance for the weight of the trailer).

Tear It Down, Start With Lights

Once we had the trailer home, we stripped the old bunks and brackets off and removed the broken/old lights. We also removed the bow rest and winch post as they would need to be reconfigured to support the mich higher bow than what the trailer had been set up for.

I made up some new light brackets as the old ones had rusted too much. I found some galvanized tie plates at Lowesdepot and bent them at 90 degrees in my bench vise. I then enlarged two of the holes that lined up with the mounting posts from the trailer lights I bought. These brackets are then secured to the frame by pinching them behind the u-bolts for the rearmost bunk brackets.

The old wiring was stripped off the trailer and the new wiring from the new light kit was strung out on the frame. Rather than use the wire nuts that came with the kit, I preferred to make the connections more permanent and reliable by soldering the wires together and covering the joints with shrink wrap. You can also dab some dielectric grease over the solder joint before you slide the shrink wrap down for even more protection but its the steel in the cheap nuts that rots rather than the copper wire.

The ground wire that comes with these kits is always pathetically short. I’ve never had a vehicle with the trailer plug close enough to the tongue to use such a short wire. So, I harvested some white wire from the “car side” harness and soldered it to the trailer harness. I then used some dielectric grease in an attempt to protect the trailer frame from salt (fool’s errand) and a stainless self -drilling screw to bond it.

New Bunks and Brackets for the Trailer

Using the measurements I had taken and the construction of our new trailer, I set about trying to find bunk brackets for adapting the trailer to the sailboat. The dropped axle of the trailer is ideal letting the keel go as low as possible. Measuring up from the keel I needed bunk brackets in the 20-24″ range given we have a 4″ tube section. This tube section, and the lack of horizontal cross members severely limited our choices for off-the-shelf bracketry. Most brackets are designed for 3″X3″ tube cross members. The cross members on the Escort are “L” channel and not suitable for u-bolts. I also refuse to drill new holes in the galvanized trailer frame as these would expose bare steel and rust quickly.

Eastern Marine Trailer Parts Super Store had only one solution for our trailer situation. And I could find no solution elsewhere. The Tiedown 24″ bunk bolster brackets would have to do. However, these are set up to have a swivel top bracket bolted directly to the top with a short bolt. If the brackets were attached to cross members, this would be fine as they would allow the bunks to pivot to the slope of the hull. However, we had to attach to the longitudinal frame members so the bunks would want to pivot forward and back rather than side to side. The solution I came up with was to use bunk stiffening bracket weldments that had a tab welded to a tube. By bolting this to the bunk bracket and using two swivel top brackets to either side of the weldment I could change the pivot direction by 90 degrees.

We then had to set about the bunk boards. I had seen a lot of boat trailers with long bunk boards strung between the brackets. It seems to me most of the board area in these cases does nothing but prohibit you from servicing the hull while on the trailer and rubbing bottom paint off. No weight is being carried more than a few inches from the brackets as the boards will simply bend away. I had also seen many trailers using round or square bunks atop the brackets and this seemed more ideal, I originally ordered only four brackets to save money, but once in hand, I realize we had too little margin for error and ordered another two.

I had to replace the wood on the engine mount as well, so I bought a sheet of 3/4″ hardwood plywood. Did not splurge for marine plywood ($$$$) so it has lots of voids in it. I also wanted to reduce the chances of point contact with the hull. The bunk carpet will only disperse a minute amount of load. I chose to cut 1/8″ luan into “inverse circles” to raise the edges of the bunk pads in hopes that they would spread the load more effectively to the edges of the bunk boards. I laminated two layers of 3/4″ plywood and then the 1/8″ luan, sanded edges round, waterproofed with deck and fence sealer (two wet coats) and then Diana stapled bunk carpet to the bunks with stainless steel staples.

Time to Get the Boat on the Trailer

With the bunks fitted to the trailer casually, we were ready to go fetch the boat as they would have to be adjusted for height and angle while setting the boat on the trailer in order to complete building a sailboat trailer. Check out the next post to see the process we came up with for transferring the boat from the jack stands to the new trailer!

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

- Forum Listing

- Marketplace

- Advanced Search

- About The Boat

- Gear & Maintenance

- SailNet is a forum community dedicated to Sailing enthusiasts. Come join the discussion about sailing, modifications, classifieds, troubleshooting, repairs, reviews, maintenance, and more!

Looking for welding plans to build trailer

- Add to quote

Hello all: I am looking for find plans to build a heavy duty trailer - for my sailboat. Capacity needs to be +/- 10,000 lbs, fin keel. It is to be used for my Catalina 27 . . . and possibly a future (slightly larger/heavier) boat in a few years. I have already sourced the running gear (axles, wheels, hitch, brakes, etc.). There seems to be a lot of plans available for a small or medium size "regular" boat trailer, but as we know, trailering a deep fin keel boat is a different matter. Any ideas or suggestions out there, fellow sail-netters? Where can I find welding plans for something like this? thx, P

Attachments

http://4.bp.blogspot.com/-45sR-U_-154/U3ksYN2g5tI/AAAAAAAAANU/_VlC0Y0guyg/s1600/P1010001.JPG Here is a custom made for a 6500# It was with the boat when I bought it. Seems well made. If you need any measurement let me know.

On the small side find and look at J24 trailers on the big side look at J105 trailers or anything TRIAD You can also look at TRIADs web sight as they have hundreds of GOOD pictures It is common to see the J24, J80 and J105 trailers which is why I bring then up

bratzcpa said: Hello all: I am looking for find plans to build a heavy duty trailer - for my sailboat. P Click to expand...

Did you try talking to Catalina? They closed their plant here in Woodland Hills, but it's just possilbe... They still have a keel mold sitting in the yard on the west side of the building, and who knows what they have inside. They've leased out their east lot for trucking storage, but I haven't seen any movement on dispostion of the property .

I'll tell you one thing you should NOT do. You should not buy the book "Trailers: How to Design and Build, Volume 1" by M.M. Smith. It is a complete waste of time and money. It is so high-level as to be useless. Do I really need to buy a book to explain to me that a trailer's electrical system should include brake lights and turn signals? Seriously. The book spends about three pages, rambling on and on, and in the end tells you nothing more than that. Or that the springs are intended to protect the cargo from bumps and potholes in the road? Given its title, I thought it might include some details on how to calculate spring loads, or determine their best location. But no, it went into no more detail than to explain that most trailers have springs, and they are to protect the cargo. Well, DUH! Volume 2 might be useful. I don't know. Fool me once, shame on you; fool me twice, shame on me. As completely useless as Volume 1 was, I was not going to throw my money away on Volume 2 (which, by the way, costs more than Volume 1). Personally, I would agree with the recommendation to go to the Glen-L site. Good luck.

suggestion.. build a cradle that will hold the boat well.. get a used flat bed trailer.. cheaper to find used then building new. Bolt the cradle to the trailer and you have a trailer to use for other things when the boat isn't on it!

deniseO30 said: build a cradle that will hold the boat well.. get a used flat bed trailer.. Click to expand...

I'm glad that it turned out so effectively and I hope it will continue in the future because it is so worthwhile and meaningful to the community. afkfdededgkcbeed

- ?

- 176.3K members

Top Contributors this Month

- Forums New posts Unanswered threads Register Top Posts Email

- What's new New posts New Posts (legacy) Latest activity New media

- Media New media New comments

- Boat Info Downloads Weekly Quiz Topic FAQ 10000boatnames.com

- Classifieds Sell Your Boat Used Gear for Sale

- Parts General Marine Parts Hunter Beneteau Catalina MacGregor Oday

- Help Terms of Use Monday Mail Subscribe Monday Mail Unsubscribe

trailer build for 25.5 fin keel

- Thread starter chad72302

- Start date Apr 6, 2018

- Hunter Owner Forums

- Ask A Hunter Owner

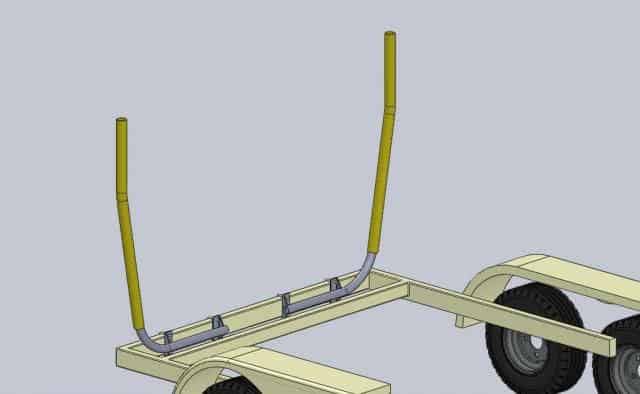

I was given a 1985 Hunter 25.5 last june. I'm a contractor. a few months prior i had done some work for a guy who lived on lake norman, a lake just north of charlotte nc. i notice the boat docked at his neighbors house, and could tell it had not been used in awhile. i asked the homeowner about it. he agreed that it looked neglected, but knew nothing else. i finished the project in april, and thought nothing more of the boat. a few months later the homeowner texts me saying his neighbor is selling the boat and the price is zero. i had never met the neighbor. a few weeks later we met up and he signed over the title. I wanted to get it to my house, where I could begin to restore it. my plan was to store it at a friends dock until i could get a trailer for it. i figured how hard could that be? turned out to be pretty hard. its the fin keel version, that drafts 4' 6". hunter also offered a shoal draft keel version in that same model. that would have been much easier. i searched all over for a fin keel sailboat trailer. they are hard to come by. i guess most fin keelers dont have trailers? suppose they just haul out periodically? after months of searching i gave up. my new plan was to build a trailer. the trailer build didnt seem to complicated. i've done some welding. but figuring where to place the uprights, and at what height was a different story. even though my uprights would be adjustable in height to some degree, my fear was that they'd be off, and have to be cut and redone. i finally settled on buying a used trailer and modifing it. this made me feel a little more optimistic about the outcome, but did nothing to solve my upright placement issue. i thought maybe if i could get a lines plan for the hull, i might be able to use it to loft full scale templates of hull sections. but i abandoned this idea too, and my project evolved again. now i was settled. i was going to start with a used trailer and build a wood frame on it, that i could then be build wood uprigths from. this would allow me to have the boat hoisted out, set on the trailer, then build the wood uprights to the hull. once completed, the hoist straps would be taken away, and i'd drive off. i'd later weld metal uprights one by one as i removed the wood uprights. soo. to my knowledge, theres is no other trailerable load comparable to a fin keel sailboat. it bears most its weight on a single point. its like towing a 6000lb, 25 foot long, 9 foot wide irregularly shaped spinning top. its spooky just to look at, scary to tow, and terrifying to design. I was haunted by visions of it laying in the street. i had to figure where to place the axles, and where to place the "keel cradle". weight distribution would be critical with it almost all bearing on a single point. technically, it should be 80% on the keel, with uprights only taking 20%. another think complicating my trailer build was that theres only one travel lift on lake norman. they're always booked, and not crazy about their lift sitting idle. this forced me to do as much preliminary work as possible. so the trailer is 21' x 6'. i printed the spec sheet on the hunter model, and used it to make a scaled version of my trailer, that I drew on a small piece of paper and then superimposed it over the hunter spec sheet, to figure where to place my axles and the keel cradle. i wanted the keel to sit directly over the axles. after getting my axles moved, i then welded two 1/4" x 6" flat stock pieces directy to the frame, spaning three cross members. it was 54" long. i then drilled six holes in the two pieces and bolted treated 2 x 6s to them. i drilled several holes in the top portion of the longitudinals of the trailer frame and bolted a 2" x 4" flat to it. i used it like a sill plate to build a 2" x 6" frame from. similar to building a deck. i replaced the coupler and lights, and then scheduled the big lift. it was lifted out and set on the keel cradle. the lift operator leveled it and left it to me. i used scrap wood to "deck" a few areas where i need my uprights to go or their braces. i used treated 2" x 4" for uprights and bracing, and pads i had made earlier. the pads were made from 3/4" treated plywood with pieces of rubber door mat glued to it. the porous texture of the door mat top adhered perfectly with adhesive and the bottom of the door mat held fast to the hull. on the bottom side of the pad, i fastened two strips of scrap wood spaced just wider than a 2 x 4. it worked well. I made it the 18 miles from the marina to my house and the boat is still standing now. hopes this helps someone.

Attachments

Crazy Dave Condon

Looks like all seasons marine. I know the lift operator. Sounds like Graham sold the boat originally as the s dealer. What is the designed or max load on the trailer or GVW? What is the load range for the each tire. What is the tire.

yes it was all seasons. didn't meet a graham, but did meet tim and joanne. I dropped your name. tim sends his best. good eye dave. the axles and tires are undersized. I cant plead ignorance either. I was going to include this in the original post, but it was already too long. when considering replacing the axle bearings, I called to price them. person I spoke to believed they were from a 2200lb axle, but she wasn't certain. I knew that by the axle diameter and lug pattern that it could also be a 3500lb. I went with this assumption, and figured I had a 7k capacity. I also figured that worst case, they were 2200, making my capacity 4400, but figured with a 4500lb boat weight plus the trailer weight, I'd be around 6000. I was OK with this. I worry less about overloading a tandem axle. I wouldn't do it with a single axle. what I didn't plan on was the boat weighing 6000lbs. I guess the extra weight came from gear, which wasn't much, and osmotic water intrusion. the bottom is covering with blisters. so know I'm at approximately 7500, which was not cool. I didn't realize how bad it was until I got on the road. it was awful. I couldn't go over 30. anything faster than that, and it would start snaking violently. so if that wasn't bad enough, the weight distribution is to far aft, also. again I didn't realize this till later, when I went to decouple at home. fortunately, I left the safety chains hooked up when I did this, because the front of the trailer rose. not gently either. the chains stopped the trailer back from bottoming out completely. it has negative tongue weight. I have to jack the back of the trailer to get the front to lower on my ball. I haven't towed it since. my goal was to get it to my house and I achieved that goal. if I did it again I would decouple to do the build. this way would know if the weight was right. I was hooked to the trailer the whole time. tires are 13". load range c. 1360lb per, I think. it was the highest load range I could get. I replaced two and the other two were good. having 4 good tires made feel a little better about being overweight, also. in hindsight, the tire size should have been a dead giveaway. but in my defense, I have a cargo trailer with a single 3500 axle. I know cause I replaced it. it runs 15" tires, and has the same lug pattern as the sailboat trailer. so, my plan is to add a third axle aft. I think this will solve my weight distribution problem, and my overweight issue. that would give me 6600lb if go with another 2200 axle, or if available a 3500lb one. adding a 3500 lb axle would give me a 7900lb capacity, and a ton of piece of mind.

whats an s dealer? dave I have plans to restore this boat. the bottom gelcoat has to come off, needs paint or epoxy all over. the main bulkhead has water damage at the chainplates, and likely under the cabin sole. I haven't yet removed it. rest of the interior is good, cushions need recovering. I also plan to modify the cockpit. removing some of the bench seating, and adding a helm. going to beef up cockpit sole too. it crunches under foot. the deck is sound, but the pop top is delaminating. I was thinking of deleting altogether. making a fixed trunk extension. like 6". that would give 6 foot of clearance. i'm pretty ambitious, and not afraid of big projects, but would like your opinion as a former dealer. is this boat worthy of all this?

The trailer sway problem is likely to be simply loading. Trailers need to be front loaded. With a single axle at least 10% of the weight needs to be on the hitch. With multiple axles I don't know how to calculate loading but I know it still must be forward. Ken

Hunter Ad Bot

And now a word from the sponsor... Click to expand

Ken. Trailer is an issue that needs to be addressed. May have a lead for a trailer used of course. However it depends on the condition of the boat before going any further. Chad. Send me a private messsage with phone. Advise lake Norman. Tim did represent hunter for me at one point. Tim is a good man to know Dave

Brian M H23

Depends on this trailer to be used. Have yet to hear from the owner and if so will advise on discussion. One other thing that also no one brought up is the forward portion of that trailer could collapse if over loaded and that too is scary. I have seen the aftermath as well as in person. I was pulling a 33 foot keel sailboat on my trailer following behind another boat 36 footer on a professional driver’s trailer when that trailer collapsed. Due to professional experience of that driver, no injury or other vehicles involved. I have designed trailers too

Honestly, looking at the photos, I think you got lucky. I would not trust that structure to go bouncing down the road with that much weight on it for any distance at all. It should be steel and, really, the weight is not supposed to be a point load. A "real" trailer is designed so that you can float the boat onto it. In other words, the keel does not touch at the bottom.

Hate to say but weight is a major issue in trailer design and the keel tray is designed to carry the load with other fixed stands/bunk boards to support the boat upright. In addition most trailers are designed for launching but there are a few only for transport. It depends on what you want to do with a trailer first. Then designing from there

@chad72302 Where are you. What do plan to do?

- This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register. By continuing to use this site, you are consenting to our use of cookies. Accept Learn more…

DIY Boat Building Plans

How to Build a Boat Trailer

Download over 500 Boat Plans. Click on the link below.

-->click here<--.

Table of Contents

Overview of How to Build a Boat Trailer

Boat trailers are an essential accessory for any boat owner. They provide a convenient and efficient way to transport your boat from one location to another, whether it’s to the local lake or across the country for a vacation. Having a boat trailer allows you the freedom to explore different bodies of water without the need to rent a trailer every time you want to go boating. One of the benefits of building your own boat trailer is the customization options it offers. When you build your own trailer, you have the freedom to design it according to your specific needs and preferences. You can choose the materials , size, and features that best suit your boat and towing vehicle. Building your own boat trailer also gives you a sense of accomplishment and satisfaction, knowing that you created something functional and practical.

Key Takeaways

- Choosing the right trailer for your boat is crucial for safe and efficient transportation.

- Building a boat trailer requires materials such as steel tubing, angle iron, and plywood .

- Essential tools for building a boat trailer include a welder, saw, drill, and measuring tape.

- Building the frame of the boat trailer is the first step, followed by adding the axle and wheels, installing the trailer hitch, wiring the lights, and adding brakes.

- Regular maintenance of your boat trailer is important to ensure its longevity and safety on the road.

Choosing the Right Trailer for Your Boat

When choosing a boat trailer, there are several factors to consider. First and foremost, you need to ensure that the trailer is capable of safely carrying the weight of your boat. The trailer should have a sufficient weight capacity and be compatible with the size and dimensions of your boat. Additionally, consider the type of terrain you will be towing your boat on. If you plan on traveling on rough roads or off-road, you may want to invest in a trailer with stronger suspension and larger wheels. There are various types of boat trailers available in the market, each with its own advantages and disadvantages. The most common types include bunk trailers, roller trailers, and pontoon trailers. Bunk trailers provide excellent support for the hull of the boat and are ideal for boats with V-shaped hulls. Roller trailers, on the other hand, use rollers instead of bunks, making it easier to launch and retrieve your boat. Pontoon trailers are specifically designed for pontoon boats and feature adjustable bunks to accommodate different sizes.

Materials Needed for Building a Boat Trailer

To build your own boat trailer, you will need a list of materials. The specific materials required may vary depending on the design and size of the trailer, but some common materials include steel or aluminum for the frame, wooden or composite boards for the bunks, and various hardware such as bolts, nuts, and brackets. It is important to choose high-quality materials that are durable and can withstand the weight and stress of towing a boat. There are several options for sourcing the materials needed for building a boat trailer. Local hardware stores and home improvement centers often carry a wide range of materials suitable for trailer construction. Additionally, there are online retailers that specialize in trailer parts and accessories. When sourcing the materials, consider factors such as cost, availability, and quality to ensure you get the best value for your money.

Tools Required for Building a Boat Trailer

| Welding Machine | A machine used to join metal parts together by heating the surfaces to the point of melting and fusing them together. |

| Grinder | A tool used for grinding, smoothing, and polishing metal surfaces. |

| Drill | A tool used for making holes in metal parts. |

| Saw | A tool used for cutting metal parts to the desired size and shape. |

| Hammer | A tool used for shaping and bending metal parts. |

| Measuring Tape | A tool used for measuring the length, width, and height of metal parts. |

| Clamps | used for holding metal parts in place while welding or grinding. |

Building a boat trailer requires a set of tools to complete the construction process. Some essential tools include a welder for joining metal components, a saw for cutting wood or metal, a drill for creating holes, and various hand tools such as wrenches, screwdrivers, and pliers. It is important to have the necessary tools on hand before starting the construction process to ensure smooth progress. There are several options for sourcing the tools required for building a boat trailer. Local hardware stores often carry a wide range of tools suitable for trailer construction. Additionally, there are online retailers that specialize in tools and equipment. Consider factors such as cost, quality, and availability when choosing where to source your tools from.

Step-by-Step Guide to Building a Boat Trailer

Building a boat trailer may seem like a daunting task, but with the right guidance and instructions, it can be a rewarding project. Here is a step-by-step guide to help you build your own boat trailer: 1. Design your trailer: Start by designing your trailer according to your boat’s specifications and your towing vehicle’s capabilities. Consider factors such as weight capacity, size, and features. 2. Gather materials and tools: Once you have your design finalized, gather all the necessary materials and tools required for the construction process. 3. Build the frame: Begin by constructing the frame of the trailer using steel or aluminum. Cut and weld the metal components according to your design. 4. Add the bunks or rollers: Depending on your boat’s hull type, add either wooden or composite bunks or rollers to support the boat during transportation. 5. Install the axle and wheels: Attach the axle and wheels to the frame, ensuring they are properly aligned and securely fastened. 6. Install the trailer hitch: Install the trailer hitch onto the frame, ensuring it is compatible with your towing vehicle and securely attached. 7. Wire the trailer lights: Connect the wiring for the trailer lights, ensuring they are properly grounded and functional. 8. Add brakes (optional): If desired, add brakes to the trailer for added safety and control during towing. 9. Test and make adjustments: Once the construction is complete, test the trailer by attaching it to your towing vehicle and loading your boat onto it. Make any necessary adjustments to ensure proper balance and stability. 10. Maintain your trailer: Regularly inspect and maintain your boat trailer to ensure its longevity and safe operation.

Building the Frame of the Boat Trailer

Building the frame of a boat trailer is a crucial step in the construction process. The frame provides structural support and determines the overall strength and stability of the trailer. When building the frame, it is important to choose high-quality materials that can withstand the weight and stress of towing a boat. To build the frame, start by cutting steel or aluminum tubes or beams according to your design specifications. Use a welder to join the metal components together, ensuring strong and secure connections. It is important to follow proper welding techniques and safety precautions to ensure the integrity of the frame. The frame should be designed to accommodate the size and weight of your boat. Consider factors such as the boat’s length, width, and weight distribution when determining the dimensions and shape of the frame. Additionally, ensure that the frame is properly reinforced at stress points to prevent bending or flexing during towing.

Adding the Axle and Wheels to the Trailer

Adding the axle and wheels to the boat trailer is a critical step in ensuring its functionality and safety. The axle provides support and allows for smooth movement of the trailer, while the wheels enable easy transportation. To add the axle and wheels, start by positioning the axle on the frame according to your design specifications. Ensure that it is properly aligned and centered to maintain balance and stability during towing. Securely attach the axle to the frame using bolts or welding, depending on your chosen construction method. Next, attach the wheels to the axle using lug nuts or bolts. Ensure that they are properly tightened and aligned to prevent any wobbling or instability while in motion. It is important to choose wheels that are suitable for the weight capacity of your trailer and compatible with your towing vehicle.

Installing the Trailer Hitch

Installing the trailer hitch is an essential step in building a boat trailer. The hitch connects the trailer to your towing vehicle, allowing for safe and secure transportation. To install the trailer hitch, start by positioning it on the frame according to your design specifications. Ensure that it is compatible with your towing vehicle’s hitch receiver and securely attach it using bolts or welding. When installing the trailer hitch, it is important to follow proper installation guidelines and safety precautions. Ensure that all connections are tight and secure, and that there is no excessive play or movement between the hitch and towing vehicle.

Wiring the Trailer Lights

Wiring the trailer lights is an important step in ensuring visibility and safety while towing your boat. Properly functioning lights are essential for signaling your intentions to other drivers on the road. To wire the trailer lights, start by running the wiring harness along the frame of the trailer, ensuring it is securely fastened and protected from damage. Connect the wiring harness to the trailer lights, ensuring proper grounding and insulation. Test the trailer lights to ensure they are functioning correctly. Check that all the necessary lights, such as brake lights, turn signals, and taillights, are working properly. Make any necessary adjustments or repairs to ensure optimal visibility and compliance with road regulations.

Adding Brakes to the Trailer

Adding brakes to a boat trailer is an optional but highly recommended safety feature. Brakes provide additional control and stopping power, especially when towing larger boats or traveling on steep or hilly terrains. To add brakes to the trailer, start by selecting the appropriate type of brakes for your trailer and towing vehicle. There are several options available, including surge brakes, electric brakes, and hydraulic brakes. Choose a braking system that is compatible with your trailer’s weight capacity and your towing vehicle’s braking capabilities. Install the brake system according to the manufacturer’s instructions, ensuring all connections are secure and properly aligned. Test the brakes to ensure they are functioning correctly and make any necessary adjustments or repairs.

Tips for Maintaining Your Boat Trailer

Proper maintenance is essential for ensuring the longevity and safe operation of your boat trailer. Here are some tips for maintaining your boat trailer: 1. Regularly inspect your trailer for any signs of wear or damage. Check for loose bolts, rust, or cracks in the frame, and replace any worn-out or damaged components. 2. Clean your trailer after each use to remove dirt, saltwater residue, and debris that can cause corrosion or damage over time. 3. Lubricate moving parts such as hinges, rollers, and winches to ensure smooth operation and prevent rusting. 4. Check the tire pressure regularly and ensure they are properly inflated. Replace any worn-out or damaged tires to maintain optimal traction and stability. 5. Grease the wheel bearings at least once a year to prevent friction and ensure smooth rotation. 6. Check the trailer lights before each trip to ensure they are functioning correctly. Replace any burnt-out bulbs or faulty wiring. 7. Store your boat trailer in a dry and secure location when not in use to protect it from the elements and potential theft. By following these maintenance tips, you can ensure that your boat trailer remains in good condition and lasts longer, providing you with many years of reliable service.

Conclusion – How to Build a Boat Trailer

Building your own boat trailer can be a rewarding and cost-effective project for boat owners. By carefully considering the factors involved in choosing the right trailer, sourcing the necessary materials and tools, and following a step-by-step guide, you can successfully build a customized boat trailer that meets your specific needs and preferences. Remember to prioritize safety throughout the construction process and regularly maintain your boat trailer to ensure its longevity and safe operation. With proper care and attention, your homemade boat trailer will provide you with years of enjoyable boating experiences.

FAQs – How to Build a Boat Trailer

What materials are needed to build a boat trailer.

To build a boat trailer, you will need materials such as steel tubing, angle iron, bolts, nuts, washers, wheels, tires, and a hitch.

What tools are required to build a boat trailer?

You will need tools such as a welder, angle grinder, drill, saw, measuring tape, and a level to build a boat trailer.

What are the steps to build a boat trailer?

The steps to build a boat trailer include designing the trailer, cutting and welding the steel tubing and angle iron, attaching the wheels and tires, installing the hitch, and adding any necessary accessories.

What is the weight capacity of a boat trailer?

The weight capacity of a boat trailer depends on the size and strength of the trailer. It is important to choose a trailer that can safely support the weight of your boat.

What safety precautions should be taken when building a boat trailer?

When building a boat trailer, it is important to wear protective gear such as gloves and safety glasses. It is also important to follow proper welding and cutting techniques to avoid injury.

Can a boat trailer be customized?

Yes, a boat trailer can be customized to fit the specific needs of the boat owner. This may include adding features such as a winch, spare tire, or storage compartments.

Written by DIY Boat Building Plans

How to Build a Boat Motor Stand

Fiberglass Boat Maintenance Tips

How to Build Boat Trailers

- Create New Wish List

- Description

by Glen L. Witt Over 100 photos, drawings, diagrams and charts, 96 pages, 8 1/2" x 11", softcover, 1996. Building your own boat trailer is the best way to get an exact fit to suit your boat. Even if you can't weld, you can still use this book to plan your boat trailer for local assembly by your own welder, and still save money. It covers everything, including axles, hubs, wheels, brakes, tires, springs, couplers, frame construction methods, and much more in easy-to-read non-technical language. It even covers handling, launching, retrieving, and maintenance. If you have had bad experiences with stock trailers, such as poor tracking, or beating the bottom out of your boat, solve the problem by building your own trailer the correct way as shown in this book. "With the help and advice from Glen-L's Trailer Book, I was able to totally rebuild my new trailer, make proper bunks to support the hull, and add keel guides for easy retrieval of my "Micro". This book is an absolute "must-have" for anyone who wants to know how to adjust the load on his trailer, how to move trailer axles to achieve better balance and tongue weight, etc. For me it was a Trailer Bible and I just want to let others know that it is a wonderful and data-filled book that will solve any trailer problems that you might have." Conbert H. Benneck, Glastonbury, CT

Related Products

How to Fiberglass Boats

How to Fiberglass a Boat DVD

How to Fiberglass a Boat Book & DVD Combo

Boatbuilding with Plywood

Fiberglass Boatbuilding for Amateurs

Fiberglass Boatbuilding Manual

Steel Boatbuilding Guide

Aluminum Boatbuilding Guide

The new cold-molded boatbuilding.

The $tingy Sailor

Diy trailerable sailboat restoration and improvement without throwing your budget overboard.

DIY Custom Trailer Tongue Extension

The one thing that my new Calkins trailer lacked compared to the old Trail Rite is an extendable tongue, a necessity at some of our local ramps. The only information on the Internet that I could find about adding a tongue extension was a universal aftermarket extension . But the cost was more than I paid for the entire trailer and I still needed to install a brake system. This looked like another $tingy Sailor project!

Two tubes are better than one

The center frame member of the Calkins trailer is 8′ of 1/8″ wall, 3″ x 4″ rectangular box tube. To make the tongue extension, I purchased 10′ of 1/8″ wall, 2-1/2″ square box tube to telescope inside it. The only obstructions were the wiring that exited the frame in the center of one side, the top two bolts that connect the side booms, and the front end of the frame that was squeezed partially closed at the factory.

I relocated the wiring exit to the empty bottom 1″ of the main tube and hammered out the front end. I removed the top two boom bolts and replaced them with a 3-1/2″ x 5″ square U bolt around the boom flanges.

To hold the inner tube in the top of the outer tube, I drilled new holes in the bottom of the front end of the outer tube for a new 1/2″ through bolt. Together with an original 1/2″ through bolt on the other end of the outer tube, they would hold the inner tube in the top of the outer tube when it was slid in, leaving a 1″ space in the bottom of the outer tube for the wiring and safety chain attachments. A third 1/2″ through bolt 2′ from the front end would hold the inner tube when the tongue is extended. I installed 1/2″ plastic conduit sleeves over the three through bolts to help roll the extension in and out of the outer tube.

Two tubes deserve two pins

I drilled pairs of 5/8″ pin holes through the inner tube to match the outer tube. This results in the tongue always being held by two pins whether extended or collapsed. I had my welding guy tack 1/8″ thick x 5/8″ ID washers on both sides of the inside tube at each of the connecting pin holes. Together, the washers take up the remaining space between the 2-1/2″ inner tube and the 3″ outer tube. Besides keeping the inner tube from sliding horizontally in the outer tube, they minimize the surface area of the inner tube that has to rub against the inside of the outer tube, which should prevent the tubes from rusting together, a common problem with the old Trail Rite tongue extensions.

Extending the tongue 8′ is as simple as removing the two connecting pins, sliding the inner tube out until the holes line up and reinserting the connecting pins. Launching from shallow ramps is no problem now.

The Bottom Line

Suggested price: $400 $tingy Sailor cost: $135 Savings: $265

How have you solved the problem of a too-short trailer?

Share this:

4 thoughts on “ diy custom trailer tongue extension ”.

Our trailer has an extendable tongue, but it seems to be rusted in for the duration – I spent too many hours with sledgehammers, drills, various penetrating oils, and even a small jackhammer, and finally gave up.

We bought a 18″ receiver extension (e.g. https://www.amazon.com/gp/product/B000E1DTG2/ref=oh_aui_search_detailpage?ie=UTF8&psc=1 ) and a deep-drop ball mount. We swap in that assembly in place of the standard ball mount / stinger to launch and retrieve. That adds close to 2′ of extension, and drops the bow of the boat several inches, so the trailer is a little closer to level, even on the sloped ramp. Together, that gains about 3″ of depth (I.e., 3″ of car we don’t have to submerge to get her to float). Not nearly as nice as a real extendable trailer tongue, but pretty cheap and easy. And probably about the same amount of hassle in the parking lot as extending the trailer tongue (although I have no personal experience there, for which I’m still bitter at that rusty trailer…).

Note: The extension is theoretically rated for Class III towing; I wouldn’t want to tow real weight with it on the road, but it’s fine for backing down the ramp.

A good compromise there, Aaron, if a couple of feet more length is all you need to launch and retrieve.

I’m looking at a few trailers for my C22. I’ve found a couple that are listed for 17-19’and I’m wondering if I can extend the trailer frame and bunks to support the boat. Any experience with extending the back-end? Any thoughts on bunks vs rollers?

Sorry, Tom, I don’t have any experience extending a trailer for a larger boat. I’ve read of others who have adapted conventional boat trailers to fit sailboats with good results, though. The prevailing wisdom is in favor of bunks over rollers so that you can float the sailboat on and off the trailer instead of winching.

Hope that helps, $tingy

Leave a comment Cancel reply

This site uses Akismet to reduce spam. Learn how your comment data is processed .

- Already have a WordPress.com account? Log in now.

- Subscribe Subscribed

- Copy shortlink

- Report this content

- View post in Reader

- Manage subscriptions

- Collapse this bar

How to build a sailboat trailer extension

This is the remarkable true story about how I built a sturdy trailer extension and got 27 stitches in the process. I recommend the former, though I included instructions on how I got the latter just in case you’re interested.

The previous owner of my Catalina 270 took her in and out of the water with a crane. Unfortunately on my lake, there are no cranes, so we have to launch the boat by backing the trailer into the lake. When the lake is low or the ramps shallow, it is necessary to extend the trailer out further into the water than the tow vehicle can go. One way to accomplish this task is by building an extension to go between the trailer and tow vehicle, which allows the trailer to be let down further out into the water.

On my prior boat, I used a strap and rolling wheel on the front of the trailer to lower the boat in. The problem with the strap (or rope, or cable) method is that you can’t push the trailer further into the water. Often times there are large ruts or pits in the dirt beneath the ramp caused by power boaters gunning their engines to push boats on and off trailers. To pass over these ruts using a strap, you have to let the boat back quickly down the ramp to build up enough momentum to roll through the ruts, and I always worried that a deep rut on one side or the other would tip the trailer to the side. It never did, but I always imagined it happening.

So this time I wanted more control over the boat, and decided to build a solid bar extension. I looked at several designs on various websites and decided I wanted one that was heavy duty enough to support the weight without needing a dolly wheel under the front of the trailer. I wanted about 15 feet of extension, and it needed to be easily installed, removed, and stowed on the trailer.

First, off to the local metal shop, where I purchased 15 feet of galvanized steel, in the same dimension as the steel on the trailer’s tongue (3″x5″). I think it’s possible to go with something smaller, but not knowing how it would handle the load I decided to stay with the original dimensions.

Next, I ordered a 2-5/8″ hitch coupler from Amazon on the front of the hitch extension, which would connect to the tow vehicle’s ball without having to switch ball sizes.

Then, I had the terrible idea of simply bolting the hitch extension alongside the trailer’s tongue. Two large bolts, spaced about 2 feet apart, seemed like they would do the trick. However, the weight of the trailer bent the bolts and the extension sagged to about 2 inches off the ground. It was enough to launch it the first year, but I knew I’d need a sturdier connection between extension bar and trailer by the time we hauled out in fall.

I ordered a 2- 5/8″ trailer ball to mount on the top of the extension bar. This ball would lock into the trailer hitch. At the back end of the bar, I planned to have two bars welded on that would hug the sides of the trailer tongue and be secured on top with a hitch pin.

The bars I chose were half inch thick steel. This is how I ended up with 27 stitches. My battery powered drill would never make it through, so I ran to the hardware store to pick up a corded drill. The drill I’d planned to buy was good, but when I got there I found a higher amperage drill on sale for less. More power for less money? Yes, please. So I walked out of the store with a 9 amp Hitachi drill.

I lifted my 25 lbs vice off the workbench and set it on the garage floor for safety. I locked the steel in the vice and started drilling, stopping every 30 seconds or so to add some oil into the hole. The whole operation felt pretty safe until the drillbit punched through the back side of the steel. That’s when the full fury of all 9 amps was unleashed. That monster drill grabbed the steel bar and 25 pound vice and spun them in circles so fast that by the time I let go of the trigger it had spun around 2 full times. I felt something had hit the back of my leg, and glancing down, realized I was in trouble. The half inch bar traveling at 9 amps had laid open the back of my calf. It was going to need stitches. And not a few, because as it turns out, half inch steel is not a very precise cutting implement.

On the drive over to the hospital, I used Intermountain Healthcare’s “ConnectCare” telehealth app on my phone. It was amazing, I could actually show the doctor a video of the wound from the car so she could tell me if I needed to go straight to the emergency department, or just a clinic. One emergency department visit and 27 stitches later, I was good to go. And I only had one more bar to drill through. It took me two weeks to get the courage to do it.

But the end result was a great trailer extension. It’s very sturdy, able to hold the front of the trailer at the same height over the full length of the bar. It also has enough ground clearance that I can attach it on flat pavement and drive it over the edge of the road onto the ramp without bottoming out. This makes work on the ramp much safer, because the trailer is never unhitched from the tow vehicle while on the incline. I also have an impressive scar on the back of my leg which I refer to proudly as “a sailing injury.”

Recent Posts

Shakedown Sail on Catalina 270

https://youtu.be/o12vftqzKog?feature=shared After an eventful spring launch, I ended up with a basically new Unsinkable 2. Here’s the first shakedown sail. More on the story later.

Key Lime Sailing Day 5 - After Thoughts

Checkout was simple. I asked what we needed to do, and was told "Just leave us a good review if we earned it!" And yes, they did. A few observations for a next trip here: It's a quick trip from...

Do It Yourself Boat Trailer Tongue Extension

- Snowboarding

- Scuba Diving & Snorkeling

While the rare trailer comes with a built-in, slide-out tongue extension, many boat trailers are simply too short for boaters to easily launch and retrieve their boats at shallow ramps without driving at least the rear wheels into the water—or worse. This is especially true for sailboats , which typically sit higher on the trailer. And amazingly, only one company can be found online making a bolt-on kit, ExtendaHitch, but it's rather expensive and may require other trailer modifications, such as sawing off the "skid leg" typically found beneath the trailer's tongue.

You could take your trailer to a welding shop to have the receiver for a removable extension welded in place, but that costs more too and is inconvenient.

Instead, you can build your own removable extension with simple tools and readily available parts that bolt together. The 6-foot extension shown here along with its own hitch coupler and the receiver hardware attached to the trailer cost only $120 for parts and took about an hour to assemble. ( Important: An extension like this is only for use at the ramp, NOT for towing .)

The Receiver Tube Mounted on the Tongue

The extension itself is a heavy steel square tube of appropriate size for the trailer. The one shown here is 2 by 2 inches square (outer dimension) of steel a quarter inch thick and 8 feet long, providing a little more than 6 feet of extension. If you can't find heavy steel square tubing like this locally, you can order it online as low as about $75 for this length. On the vehicle end of the extension is mounted a standard hitch coupler , available in different bar sizes and for different size trailer balls.

The other end of the steel extension tube slides into the steel receiver tube that is mounted on the trailer tongue—this receiver is just like the receiver piece on many trailer hitch class 2 or 3 receivers mounted on vehicles. It comes with a half-inch hole in which you place a standard trailer hitch pin like the one shown (after drilling a hole in your extension tube to match).

You may have to get creative with where and how you mount the receiver (available in 12- and 18-inch lengths) on top of or below the trailer tongue. (You don't want it to mount if on the side, normally, because the greatest torque forces are vertical, and a side-mount could twist free or distort under stress.) In this example, the owner mounted the receiver above the tongue to avoid having to remove the triangular skid leg under the tongue. The spacers are needed to raise the receiver such that the extension clears the latch on top of the original trailer coupler. These spacers were scrap steel—very heavy rectangular tube cross-sections. Hardware-store brackets were used to bolt the receiver in place.

Can you spot the flaw in this arrangement?

A Heavier Receiver Mount

The previous photo showed the receiver mounted with 3/8-inch bolts through clamp pieces from a U bolt— the heaviest off-the-shelf clamps from the local big-box hardware store. An engineer who was consulted was concerned what would happen with any twisting or sideways force on that mounting, so the boat owner decided to beef up the mount as shown here. Quarter-inch steel bar was cut and drilled to make the clamp pieces, secured with 1/2-inch galvanized bolts. The original two clamps were kept for added strength but repositioned. For straight in-and-out trailer use at the ramp, this arrangement has proved more than strong enough for this owner's boat under 2000 lbs, though of course it should not be used for trailering the boat more than the short distance up and down the ramp.

If you have a larger boat or want an extension as strong as can be, you can have the receiver welded to the trailer in an appropriate place.

Welded Receiver

In this trailer, there was not a convenient place to mount the receiver on the trailer's tongue, so the owner had it welded farther back at the front of the trailer's frame. This required a longer extension tube to achieve the desired extension, but the long extension piece is easily stowed along the bottom of the trailer as shown here. In principle, this works just the same as the bolted-on version.

A tongue extension is easy to use and makes launch and retrieval much easier. To launch, simply back the trailer to the head of the ramp at a level point, aligned so that you will go straight back. Chock the trailer's wheels and uncouple it from your hitch, pull forward and slip the extension bar in place, pin it, and hitch the extended coupler to your vehicle and back it in.

Ultimately this is a much more controlled launch than the alternative chain or rope/webbing some boaters use to let an unhitched trailer roll down the ramp away from the vehicle. The problem is that the tongue of the trailer must be held up, requiring the use of a wheeled tongue jack or other wheels once the trailer is unhitched. Wheeled tongue jacks are not designed for the loads involved and seldom last long. Some boaters go to the trouble to mount other, large wheels to support the tongue and then use a chain extender to let the trailer roll down and to haul it back up, but the chain approach doesn't offer the same control—and ultimately costs as much as or more than the simple tongue extension you can craft yourself.

- Learn How to Sail a Small Sailboat – 1. The Parts of the Boat

- Raster versus Vector Charts in Nautical Use

- How to Rig a Preventer Line

- How to Make Your Own Stern Pulpit Rail Seat

- Choosing a Centerboard or Fixed Keel Sailboat

- The Basics of Navigation

- How to Use Roller Furling

- How to Use a Topping Lift

- Using AIS on Your Sailboat

- Where Registration Numbers are Placed on a Boat

- How to Anchor a Sailboat

- How to Install a Voltmeter on Your Boat

- Comparing AIS Boating Apps: Ship Finder, Marine Traffic, Boat Beacon

- How to Use a Mainsheet Traveler

- How to Boat

- Control Your Tiller Without a Tiller-Tamer

Affordable Sailboats You Can Build at Home

Key Takeaways

- There are many sailboats that anyone can build from home depending on tastes

- Budget will be the biggest deciding factor on a majority of the process

- Consider kits that come with most of what you need or choose ones that are all-inclusive

- Design complexities and new materials may make the building time process longer

- Plan the best you can ahead of time to save money and your working hours

Buying a sailboat can be expensive, but building your own can save you money. So what are sailboats you can build from home?

Sailboats that you can build from home will likely be a small boat under 20 feet. These could be from many different boat suppliers such as B&B Yachts, Brooks Boat Designs, and Chase Small Craft. Boat plans will vary based on your budget and how much time you have on your hands.

Based on my previous experience, building your own boat will take much longer than if a professional were to do it. You also have to be able to study plans, consider various sailboat designs, and have tons of supplies such as fiberglass tape or fiberglass cloth. On top of that, you will also have to be good with your hands.

Table of contents

Top 10 Affordable Sailboats Anyone Can Build at Home

Building your own pocket cruiser or other styles from boat plans is an impressive feat, as this will need dedicated time and money to assure your boat sails safely. Boat building takes a lot of patience as well, especially since this will not be completed in a fast manner.

Finding boat plans and materials that fit your budget will be key to being able to complete the project. The time it takes to complete these projects will vary on your overall experience and needs. Below are 10 of the most affordable sailboats that you can build in the comfort of your home.

B&B Yachts

B&B Yachts have 14 different boat plans you can choose from to find the boat of your desires. Their shop is located along the Bay River in North Carolina where they construct all of the kits and have a 100 foot dock to show off your project once you complete it.

One popular model to check out is their Core Sound 15, as it is the perfect size for those wanting to build a modest size boat for a handful of people on board. Their website features some videos of completed projects and the plans or kits for purchase.

- 14 different models to choose from plus some dinghies

- Various monohull and multihull options

- Friendly customer service with attractive prices

- Might be too many options for some that are indecisive

- Not ideal for those wanting to have a motor sailer

Brooks Boat Designs

Brooks Boat Designs has a handful of options to consider for your next sailboat building project. They are located in Brookline, Maine and give the option to buy the kits or have them build one from scratch for you. They have plenty of knowledge, so do not be shy to ask about modifications or custom features you are looking for.

Depending on your specifics, they can attempt to accommodate some of their plans to help fit your desired outcome. By checking out their site, you can see many examples of their construction in progress and what the boats will look like when completed.

- Offers a variety of kits

- Plans vary around $50 and up, while materials will obviously add more costs

- Some plans can be rowing boats that can convert to sailboats

- Might take a while to hear back from them, as their contact section is a little outdated

- Their plans may not accommodate a ton of extras for your taste

Chase Small Craft

Chase Small Craft offers a simple process for building boats. Their kits are equipped with everything you need and will help save you time than just buying the materials outright and other parts you could need. This is arguably one of the best bang for buck instances if you want to save time and money searching for pieces to your boat.

They are located in Saco, Maine and will ship everything to your home from there. All the necessary materials are included and all you need are the proper tools and working space.

- All-inclusive kits with what you need

- Tons of knowledge on their site for boat building

- Easy process to order and customize

- Complete kits can range over $20,000 for larger boats

- Kits may take up to eight weeks to ship out

Chesapeake Light Craft

You can expect high-quality boat kits from Chesapeake Light Craft . They feature 18 different sailboat kits that vary from eight to 20 feet in length. This should be more than enough to find one for you if you are newer to boat building.

They also have a wide variety of other kits in addition to the sailboat, in the event that you wanted to order a small kayak or paddleboard in addition to your sailboat. The prices vary considerably when considering a small or larger boat, so check the complete list of options to in order to potentially fit your needs.

- Plenty of sailboat offerings to choose from

- Different beautiful hull form options to consider

- Easy to build and perfect for sailing

- Only has basic materials needed for kit, so you may need to purchase other items

- Has epoxy shipping fee no matter if you pick up item

Dudley Dix Yacht Design

Dudley Dix Yacht Design has an extensive list of plywood and single skin sailing boat options. They have plenty of sail plans and kits to consider depending on your goals. These follow a classic look for sailboats, which are aesthetically pleasing.

If you are wanting one to accommodate a small family, they have more than plenty to look through. The cost is not as bad compared to others, but keep in mind that you may need to throw in your own supplies or specific tools to get the job done.

- Plans start at $30 and range up to $7,500 or more for kits

- More than enough of options to consider

- Affordable variety of sailboat offerings

- Might be too many options for those new to sailing

- Most are wood without the use of aluminum or steel

Farrier Marine

If you are in search of a multihull to build, then Farrier Marine is what you need. They offer a unique folding catamaran that is trailerable and give you the option to build it yourself. This not only makes it an appealing option, but anyone can take this multihull boat wherever they want with ease.

It features a thorough construction guide once you receive all of the materials. These also come with stainless steel fasteners and an aluminum mast for high-quality materials. Pricing will vary since you must request which model type you are considering.

- Ability to build a unique catamaran

- In-depth construction guide to help

- Easily handled and trailerable

- Price may be too high

- Limited offerings since only a few multihull options

Glen-L Marine Designs

Building a boat from Glen-L Marine Designs can save you time and money. They feature an easy system to order and receive the kits, as well as an in-depth guide to building them. This is an appealing option compared to most boat kit sellers.

The beauty about Glen-L is that anyone can build these from scratch, so you do not have to be the best boat builder in the world to get it done. They offer guides and helpful insights from their team to point you in the right direction. Plans vary around $15, while kits can range well over $1,000 depending on boat size.

- Nearly 50 designs to choose from

- Complete guide to help anyone build it

- Plenty of price points depending on size

- Might be overwhelming with the amount of options

- Could take a while to get parts since they are popular

John Welsford Boat Designs

John Welsford Boat Designs invites new and veteran boat builders that want a taste of quality small wooden boats. The boat plans are designed to meet your specifications and are catered to your desires.

There are seven sailboat designs to choose from so you do not feel overwhelmed in the process. However, they do not sell kits all the time, so you would need to have the materials or be on the lookout for the best prices when they are available.

- Seven sailboat plans with different sizes

- Quality boat builder and supporting community

- In-depth knowledge provided to you when you order

- Might be too small of boat size

- Kits are not always available

Iain Oughtred

There are plenty of options on the wooden boat store, but you should narrow down your search for Iain Oughtred’s line of sailboat kits and plans. There are 25 different plans to choose from, which should accommodate most everyone looking to build their own boat.

While they do offer some kits, they do not routinely offer sailboat kits. You would need to purchase all of the materials if you are considering one of their sail plans. Keep this in mind if you are considering, as you would need to hunt down the parts yourself.

- 25 different sailboat plans to look through

- Various sizes to contemplate for you sailing needs

- Prices will vary but are not bad compared to market

- No sailboat kits, only plans

- Newer boat builders might find too many options unappealing

Paul Gartside Boat Builder and Designer

Gartside Boats is a boat builder company based in Long Island, New York that showcases a variety of boats from traditional and newer methods of boat building. Within that variety, they have boat plans meant for six to 50 feet in length.

With an abundance of options, you will need to contact them regarding prices and any customizable options. Kits may vary as well, as they typically design in-house and build for you.

- Experienced boat designer that can accommodate with custom plans

- Many options are trailerable

- Can have plans for up to a 50 foot boat

- You will need to contact them for prices

- Customized options may make process more complicated for new boat builders

How Much Does it Cost to Build a Sailboat at Home?

As you have likely already done so, the math between building your own boat and buying one may be a huge difference. Likewise, you may even enjoy the challenge of taking an older boat that is gutted and restoring with parts from a kit to build one new again.

But how much does it cost exactly to build a boat from the comfort of your own garage or workshop? The prices are going to vary dramatically depending on your situation and material needed to get the job done. In addition, the time that it takes to complete this will also vary.

Sail plans are rather inexpensive if you are aiming to build a small boat. These plans allow you to see the workings of the boat design and what you need to build the boat.

Without these plans, you will not know the exact details of the design and it can cause major issues with the boat’s hull or other areas of the boat. Think of these as the backbone or instructions of the boat’s infancy before being built.

Price Per Square Foot

You should assume to pay anywhere between $300 to $600 per square foot if you are interested in building a boat. Buying a kit outright can be a good way to save time, but oftentimes these do not come with everything you need.

Instead, you should try to source as much of the materials at the best price as possible. Thinking ahead is part of the process and you might be able to score a deal at a lumber yard or hardware store for parts.

Boat Designs Matter

The design of the boat will be much different from one boat to the next, regardless if they are the same size in length. If you are pondering boats that range anywhere between 16 and 20 feet, you should factor in the shape of the hull, any rigging, and various appendages.

Prices tend to increase when there are more complexities within the designs. If you are considering a kit with more details than others, you will also have to pay more for the designs on that as well.

Kits Can Differ

It is important to understand that all kits are not going to be the same. As you gander at sailboat kits online to stitch together, you need to thoroughly look over to see if you have everything you need before buying.

It would also be at your advantage to ask the seller if any additional parts or supplies are needed. This may change your dynamic on the kit buying process and you may pass up one for another if it has everything you need. An all-inclusive kit may cost several hundred, if not thousands, of dollars more to have the convenience of everything in the bundle.

Construction Approaches

Some boat plans may require you to have certain tools to get the job done. This means special saws or planers, which the average person simply does not have.

Purchasing specialty tools might be expensive upfront and hard to find depending on what it is. Your best bet would be to check locally for others trying to sell their tools or consider a boat plan that does not require extensive tools to finish the job.

How Long Does it Take to Build a Sailboat?

An easy to build sailboat could take a while to build from scratch. Many different variances come into play that are difficult to pinpoint for everyone. But how long is that exactly and how will your experience play into this?

A fun project to sail in the wind could take you several months to well over a year depending on the boat plan and how big your boat is going to be. In addition, the materials all need to be accounted for prior to starting in the event a hardware store does not have them in stock.

Time Varies

The time that passes for simple boat designs on small sailing vessels can be done in a few weeks. This is assuming you have everything you need and work non-stop around the clock.

Certain complex situations may make the process long, such as the difficulty of working with some materials. If you are a skilled laborer, it may take you half the time compared to a novice. The amount of time it can take will vary on your availability and skill level.

Planning ahead will undoubtedly offer the most time-saving features. It also helps if you can tackle parts of the project at your own pace.

Complexity of Design

The design of the boat may make the construction process longer. For example, it may take you longer to build a catamaran compared to a similar lengthed monohull.

More complex designs might require more materials, therefore making the process a bit longer to complete. Furthermore, you will also need more experience working with difficult designs and that will affect you more as a newbie.

Be sure to manage your expectations well and do not allow yourself to become too stressed over this fun project. If you can, seek expert boat building advice from a local builder or the company you purchased sail plans through.

Quality Materials

The quality of the materials will matter significantly when building a boat and will greatly affect the time it takes to construct it. Handling fiberglass or carbon fiber might require specialty tools, while wood also demands a certain level of craftsmanship.

If you are not skilled at working with the material at hand, it might affect the quality of the build and you may have to go back to fix mistakes. This will definitely add more time to your project, because mistakes are bound to happen with your first project.

To save time, consider adding the tools and materials throughout the year or as often as your budget allows. You may want to try testing your skills on fiberglass or other materials to get a feel for how to work with it.

Related Articles

Daniel Wade

I've personally had thousands of questions about sailing and sailboats over the years. As I learn and experience sailing, and the community, I share the answers that work and make sense to me, here on Life of Sailing.

by this author

Best Sailboats

Learn About Sailboats

Most Recent

Best Small Sailboat Ornaments

September 12, 2023

Best Small Sailboats With Standing Headroom

December 28, 2023

Important Legal Info

Lifeofsailing.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon. This site also participates in other affiliate programs and is compensated for referring traffic and business to these companies.

Similar Posts

Discover the Magic of Hydrofoil Sailboats

December 11, 2023

Best Bluewater Sailboats Under $50K

Hunter Sailboats: Are They Built for Bluewater Cruising?

August 29, 2023

Popular Posts

Best Liveaboard Catamaran Sailboats

Can a Novice Sail Around the World?

Elizabeth O'Malley

June 15, 2022

4 Best Electric Outboard Motors

How Long Did It Take The Vikings To Sail To England?

10 Best Sailboat Brands (And Why)

December 20, 2023

7 Best Places To Liveaboard A Sailboat

Get the best sailing content.

Top Rated Posts

© 2024 Life of Sailing Email: [email protected] Address: 11816 Inwood Rd #3024 Dallas, TX 75244 Disclaimer Privacy Policy

18 Homemade Boat Trailer Guides Plans You Can DIY Easily

Boat trailer guides might seem insignificant but are major life-savors when it comes to loading and launching your boat . Especially if your boating location is windy and you don’t have an extra set of hands to help you load your boat, trailer guides are non-negotiable!

Luckily, boat trailer guides are cheap and easy to DIY. Yes, trust us, you can DIY them all on your own, even if you’re a beginner!

Here are 18 DIY boat trailer guide ideas to assist you with the project.

Table of Contents

1. Affordable and Homemade Boat Trailer Guide Beginner-friendly Tutorial

2. 10-step guide on making a homemade boat trailer guide, 3. tall led boat trailer guides perfect for dark use, 4. homemade boat trailer guide posts – benefits and diy instructions, 5. $20 cheap homemade boat trailer guide using pvc, 6. boat trailer guides diy in 6 steps, 7. 2 inch pvc pipe diy boat trailer guides, 8. homemade pvc diy trailer guides – tips and suggestions, 9. light-attached diy boat trailer guide post, 10. boat trailer guide ons – benefits and types, 11. install diy boat trailer guides for under $20, 12. homemade trailer guide ons – brief instructions, 13. diy boat trailer guides for loading and backing up, 14. budget-friendly homemade boat trailer guides, 15. diy trailer load guides by powerboat television, 16. diy boat trailer bunk guide modification tutorial, 17. how to install boat trailer guide posts, 18. step-by-step instructions on how to build pvc boat trailer guides.

Wayne, the boat guy, is amazing at instructing his viewers at various boat-related DIYs. If you don’t believe our words, just look at how clearly he walks his viewers through the materials, tools, and the entire process of making boat trailer guides .

This tutorial, given how detail-attentive is the Youtuber at giving instructions, is very beginner-friendly. So, if this is your first attempt at DIY trailer guides, this is the video you need to watch.

James Harvy , in this written DIY tutorial post on BOATING BASICS ONLINE, provides his readers with the supply list for the DIY and 10 brief step-by-step instructions to complete the homemade trailer guide project.

This DIY uses PVC40 PE 10 ft pipe and a few other readily available supplies. What’s more, BOATING BASICS is a great resource site for boat fanatics like you!

Loading your boat into the trailer can be a real hassle during the late evening or the early morning. On top of marker bulbs in the trailer, the Youtuber decided to add guides containing marker bulbs for convenient use during the dark.

The project by Marine Trout Whisperer features a 10 ft 2 inch PVC, and a few other supplies, which the Youtuber demonstrates at the beginning of the video. He has further mentioned some of his favorite products for the DIY, along with their purchase links in the description box.

By now, we believe you are aware of all the benefits trailer guides provide. Nevertheless, if some of you are still new to trailer guides, Ride the Ducks of Seattle has perfectly elaborated on the topic.

Further in this post, find all the supplies you’ll need to DIY your own trailer guides, followed by 7-step instructions on the DIY process.

The Youtuber from PUREMAT PURSUIT DIYed boat trailer guides using 1.5 inch PVC pipe and U-bolts for about $20. He mentions in the comment that he simply used a table saw to cut notches for U-bolts in the PVC pipe.

He demonstrates the entire DIY to his viewers . The process is fairly easy and quick to follow. If you doubt that 1.5 PVC is not enough to handle your boat, you can definitely size up accordingly.

What are the items necessary for boat trailer guides DIY? How do you actually make it? For beginners, these questions bombarding their heads are difficult to sort out.

To your rescue, here’s a simple and easy-to-follow written tutorial on DIY boat trailer guides by GONE OUTDOORS. We hope it helps!

The Youtuber from Jordan Michael Fishing makes trailer guides using U clamps and 2 inch PVC pipes to load his Jon boat with ease. He walks his viewers throughout the DIY process and explains every nitty-gritty detail of the project.

If you’re into fishing, you’ll love the fishing vlogs on Jordan Michael Fishing . Do check them out!

Are you planning to attempt at PVC boat trailer guides DIY? Well, if yes, this thread on the iBOATS forum is a must-read!

The user gt2003 is considering adding trailer guides to his boat trailer with tubing of 2’’ by 4’’ and isn’t yet sure which method of DIY to follow. He has asked his fellow users for tips for the project. There are some pretty solid information and resources shared on this thread.

If you’re planning to DIY boat trailer guides, we’d definitely recommend you build one that has a light guide attached to the posts, as it is very efficient for late evening or early morning uses.

The Youtuber from Camps Outdoors walks his viewers through the entire DIY process. Watch the video and let us know what you think of this DIY.

If you’re seeking a resource that provides you with insights on boat trailer guides , this post by Our Recipes for Success is perfect for you!

Are you aware of the types of boat trailer guides? They are – post guides, roller guides, and bunk guides. In fact, this post further features the pros and cons of different boat trailer types. You’ll definitely benefit from this post!

The Youtuber from GetOutTheHouseGoFish builds PVC 40 PE trailer guides for his 14 ft Mcclain boat trailer for under $20. He has mentioned all the supplies, their dimensions, and the cost for the DIY trailer in the pinned comment in the comment section.

For fishing enthusiasts like you and us, this channel is definitely binge-worthy! Please make sure you check their video out.