- MEO Class 4

- _Epareeksha MCQ

- Machineries

- _Main Engine

- _Aux Engine (D/G)

- _Air Compressor

- _Freshwater Generator

- _Hydrophore

- _Refrigeration

- Naval Arch.

- Electricity

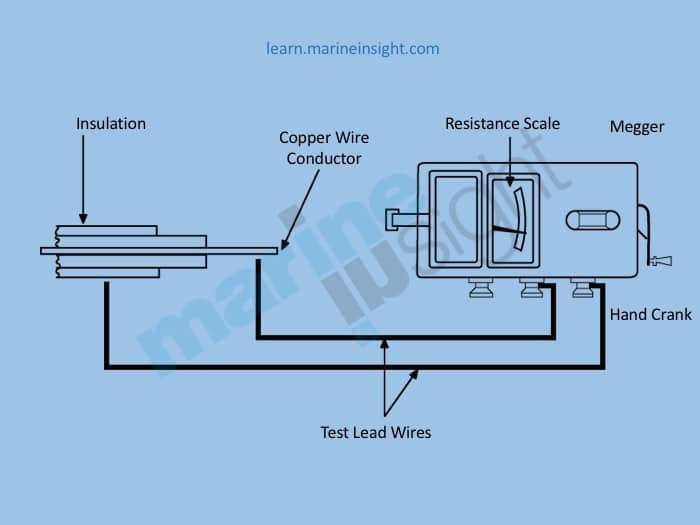

Insulation Resistance Test Or Megger Test Procedures With Circuit Diagram

- Megger testing instrument is a high resistance Ohmmeter with a build in generator

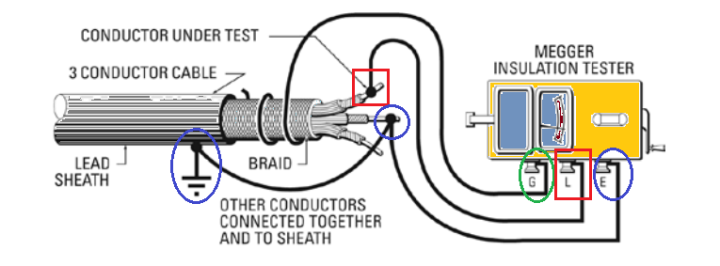

- It is equipped with three connections Line Terminal (L), Earth Terminal (E) and Guard Terminal (G)

- Resistance is measured between the Line and Earth terminals

- The “Guard” terminal is provided for special testing situations where one resistance must be isolated from another.

- The generator can be hand-cranked or line-operated to develop a high DC voltage which causes a small current through and over surfaces of the insulation being tested

- Which is measured by an ohm meter having an indicator scale

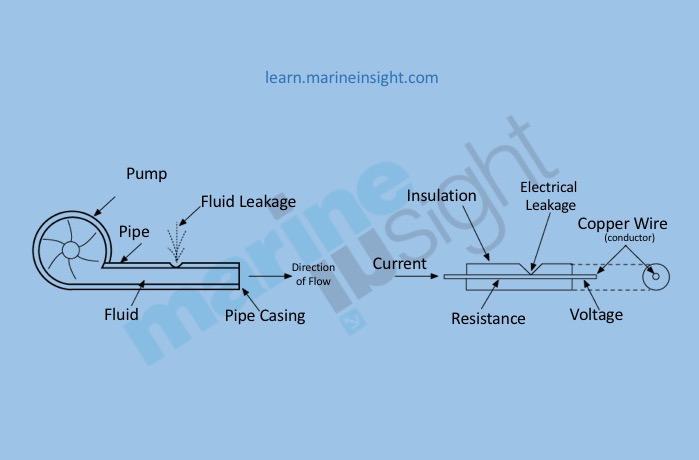

- An insulation test is carried out to test the integrity of the insulation between conductors.

- Which help to find the short circuit problems in the circuit

- It also serves as the best guide to indicate the health of the equipment

- Test the megger before use, whether it gives INFINITY value when not connected, and ZERO when the two terminals are connected together and the handle is rotated.

- To do the test you ensure the cable is disconnected from any devices (megger normally work on 500v, 1000v testers for higher voltage testing).

- Make sure that no eddy current in the device by earthing it.(very important)

- Instrument should be in normal working temperature because resistance is related to temperature.

- Ensure both ends of the cables are separated from each other (connect one end in terminal strip if necessary).

- Now connect the megger terminals to the conductors which has to be meassured

- Then hand crank the generator and a high DC voltage generated which causes a small current through and over surfaces of the insulation being tested.

- If the Reading shows Infinity means the conductors having good insulation.

.jpg)

>> Your Comments are always appreciated... >> Discussion is an exchange of knowledge It Make the Mariner Perfect.... Please Discuss below...

Very informative and nicely explain...........

Thanks come again..

How to be sure that by cranking we are developing 500vDC

It is not necessary to produce 500v.. Deflection of pointer increases with the increases in voltage in the external circuit and also decreases with the increase in current. That is, resultant torque is inversely related to current and directly related to voltage

Thanks a lot

Our website uses cookies to improve your experience. Learn more

Contact Form

Royal Navy Ship HMS Trent Seizes Cocaine Worth £40 Million In The Caribbean Sea

Seafarers Hospital Society Launches Pilot Project To Support Women At Sea

Hydrocell Launches The First Hydrogen-Powered Boat

Indian Port Workers Call Off Strike After Agreeing To New Wage Settlement

Ohmmeter – Construction and Operation Explained

The most important factor for the staff working onboard ships (or in any other industry) is – the personal safety and the safety features incorporated in machinery and systems.

Electrical components and mechanical systems present in the engine room are mainly maintained by the electrical officer .

The routine maintenance for electrical machinery involves checking of insulation resistance, which is done by an instrument called “ohmmeter”.

The insulation resistance test is done to ensure the integrity, i.e. to resist the current flow outside the equipment, and keeping it within the dedicated parts.

The measured “IR” (Insulation resistance) can be of a wire, cable or motor/generator windings. In simple terms, every electrical insulation should have the opposite characteristic as the conductor.

Related Read: Importance of Insulation Resistance in Marine Electrical Systems

For e.g., in the pump casing and pipes in a water carrying system acts as the insulation, which prevents the leakage of water. Similarly, in an electrical wiring system, the wire insulation prevents the leakage of current which is carried in a copper wire.

Table of Contents

Insulation Resistance – Importance And Causes of Decrease

Insulation resistance (I.R) is a critical parameter as it’s directly related to personal safety, the safety of machinery and power reliability.

The I.R value of electric devise changes with ageing, mechanical and electrical stresses, temperature, contamination, atmosphere, humidity etc.

It is therefore important for the engineers and electrical officers to identify this detection to avoid any accidents on board ships because of electric shock.

Another common cause of the decrease in the value of insulation resistance is the ingress of water. If the electrical equipment is wet due to freshwater, it can directly be dried out for checking the IR values.

However, in the case of seawater ingress, the first step is to wash it with fresh water to remove the salt deposits which will cause corrosion of metal parts and insulating surface.

Remove oil and grease from such equipment using a suitable solvent.

Any wet equipment on the ship is susceptible to voltage breakdown. Therefore, when using ohmmeter at the drying out stage, low voltage ohmmeter insulation tester (100 or 250 VDC) to be used.

If low voltage ohmmeter is not available, using slow cranking in a mechanical type 500 V ohmmeter can be done to achieve the results.

Sometimes, electrical ohmmeter is also provided with a test range in kilohms (kW). This test range measurement is the ideal initial check to be made on flooded equipment.

Why is Ohmmeter Testing Done?

As mentioned earlier, the insulation resistance of an electrical system degrades over time because of several factors. The insulation resistance needs to be tested to check the insulation quality (punctures in insulation) of the electrical system and to avoid any major or minor electrical shocks to operators.

Thus ohmmeter testing is carried out to find out information on leaking current and the areas where insulation has deteriorated because of excessive moisture and dirt in the electrical circuits.

Any specific circuit found faulty is then isolated and replaced/repaired to avoid any further problems and ensure the safety of the crew.

Use of Ohmmeter on a Ship (And in other industries)

The Ohmmeter is widely and frequently used by the ship’s officer for the following jobs:

- Testing an Earth/Ground connection

- Battery Testing

- Relay Testing

- Watthour Meter Testing

- Oil Testing

- Transformer Testing

- Circuit Breaker Testing

- Cable Fault Testing

- Power Quality Analysis

- Power Factor Testing

- Low Resistance Testing

- Motor winding testing

- Alternator winding testing

There is no fire hazard related to Ohmmeter insulation tester when used in a normal atmosphere. However, when using the instrument for testing equipment located in inflammable or hazardous atmospheres, it may lead to an explosion due to the spark created, when using the instrument.

Do not use the ohmmeter test equipment in an explosive atmosphere (such as the deck of an oil tanker ship ).

Types Of Ohmmeter

Ohmmeter is a portable instrument which is used to measure the insulation resistance of the electrical machinery or system. It can be battery operated or mechanically operated (hand crank dc generator) and gives a direct reading in ohms. For this reason, it is also called as ohm meter.

Onboard ship, different systems are present with large voltage ratings and therefore ohmmeter comes in the range of 50, 500, 1000, 2500, and 5000 V, thereby making ohmmeter meter suitable for applications on normal voltage equipment to more demanding high-voltage applications .

The categories of an ohmmeter test equipment can be divided into two:

- Electronic Type (Battery Operated)

- Manual Type (Hand Operated)

There are other types of ohmmeter available in the market, which is operated by an attached motor requiring an external power source for rotation.

This motor then rotates the generator fitted in the ohmmeter. As the overall size of such meter increases due to the addition of a motor, and their dependency on a power source, they are not much preferred for use on ships.

Electronic Type Ohmmeter:

The electronic type ohmmeter, also known as electrical ohmmeter, is compact of all types and uses a battery for operation. The important parts of this ohmmeter test equipment are:

Digital Display:- To show the insulation resistance value in digital form

Testing Wires:- Two-wire leads for connecting ohmmeter with an electrical external system for testing the later.

Selection Switches:- Different parameter ranges are provided on the meter, which can be selected by using the selection switches.

Indicators:- Different indicators are incorporated into the instrument to give a visual and audible indication when the instrument is ON, for a warning, parameter status etc.

The construction and parts of electrical ohmmeter will vary depending upon the manufacturer, however, the basic construction and operation remain the same.

Advantages Of Electronic Ohmmeter

- Has a very high measurement accuracy

- Easy to operate for one person

- The digital display makes it easy to read the IR value

- Robust and safe to use

- Less maintenance as compare to other types

- Works well in congested spaces

- Handy and compact to carry

- Less time-consuming operation

Disadvantages of Electronic Ohmmeter

- Requires an external source of energy to energize i.e. Dry cell

- High initial cost

Handheld Type Ohmmeter:

The handheld type ohmmeter is still used on the ship as it provides service without the need for battery and external power source. The main parts of such ohmmeter testing unit comprise of:

Display:- An Analog display is provided, which is a pointer and a scale, to show the IR value recording.

Hand Crank: As this a manually operated ohmmeter, a hand crank is provided which can be rotated to generate the required voltage, which runs through the electrical system for an insulation resistance test.

Wire Leads:- Two-wire leads are provided which can be connected to the electrical system which needs to be checked.

Advantages of Hand Operated Ohmmeter

- No external source required to operate

- An excellent choice for emergency use

- Cheaper than the electrical ohmmeter

Disadvantages of Hand Operated Ohmmeter

- At least 2 ship staff are required for operating handheld ohmmeter. one for rotating the crank and other to connect wire leads to test the IR of the equipment

- Not highly accurate as electronic ohmmeter as the value will vary with the rotation of the crank.

- It needs a stable place to operate and record the IR value, which is a little difficult to find at work sites.

- Unstable placement of tester may impact the result of IR value.

- Provides an analogue display result.

- Require very high care and safety during the use of the same.

- Time-consuming operation

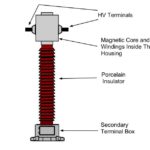

Principle Of Ohmmeter Operation

The ohmmeter works on the principle of the moving coil instrument, which states then when a conductor carrying current is placed in a magnetic field, a force is exerted on the conductor.

As seen in the figure below, when the current-carrying conductor comes in the magnetic field of the permanent magnet, a defecting torque is produced, which moves the pointer in the scale.

Construction Of Ohmmeter

The important construction features of Ohmmeter consist of following parts:

- Control and Deflecting coil : They are normally mounted at a right angle to each other and connected parallel to the generator. The polarities are such that the torque produced by them is in the opposite direction

- Permanent Magnet : Permanent magnet with north and south poles to produce a magnetic effect for deflection of the pointer.

- Pointer and scale : A pointer is attached to the coils and end of the pointer float on a scale which is in the range from “zero” to “infinity”. The unit for this is “ohms”.

- D.C generator or battery connection : Testing voltage is supplied by hand-operated D.C generator for manual operated Ohmmeter and a battery and electronic voltage charger for automatic type Ohmmeter.

- Pressure coil and current coil : Provided for preventing damage to the instrument in case of low external source resistance.

Working Of Ohmmeter

The voltage for testing is supplied by a hand generator incorporated in the instrument or by battery or electronic voltage charger. It is usually 250V or 500V and is smaller in size.

- A test volt of 500V D.C is suitable for testing ship’s equipment operating at 440V A.C. Test voltage of 1000V to 5000V is used onboard for high voltage system onboard.

- The current-carrying coil (deflecting coil) is connected in series and carries the current taken by the circuit under test. The pressure coil (control coil) is connected across the circuit.

- Current limiting resistor – CCR and PCR are connected in series with pressure and current coil to prevent damage in case of low resistance in the external source.

- In hand generator, the armature is moving in the field of a permanent magnet or vice versa, to generate a test voltage by electromagnetic induction effect.

- With an increase of potential voltage across the external circuit, the deflection of the pointer increases; and with an increase of current, the deflection of pointer decrease so the resultant torque on the movement is directly proportional to the potential difference and inversely proportional to the resistance.

- When the external circuit is open, the torque due to voltage coil will be maximum and the pointer will read “infinity”. When there is short circuit the pointer will read “0”.

General Inspection of Ohmmeter

– Check for loose connections, defective insulation, and cleanliness

– Check meter stop and pointer for damage

– Check the carrying case for corrosion, foam fungus etc.

– Check for easy cranking arrangement for mechanical ohmmeter

– Check the foam rubber lining if fitted

– Check the battery level for digital ohmmeter

– Check all indicators are working fine

General Maintenance of Ohmmeter:

- Digital multimeter is provided with a fuse. Replace it if the ohmmeter is not working

- Clean the surface from dust, dirt, grease fungus etc.

- Remove dust or dirt from terminals with a soft brush

- Clean the display using a soft cloth

- Clean the cables, meter glass, and the exterior surface with a clean, soft cloth. Dampen the cloth with water if required

What Things to Record After an Ohmmeter Test?

When performing an ohmmeter test on machinery or equipment, the following things to be recorded:

- Name and location of the equipment/ wiring

- The date on which the test is performed

- The Insulation Resistance values of test results along with time

- Range, voltage, and serial number of the ohmmeter instrument used

- The temperature of the apparatus during the time of the IR test

- When doing IR test of bigger machines such as alternator, transformer etc. wet and dry bulb temperatures and dew-point determinations to be noted

- Insulation resistance measurement corrected for temperature

Always remember to disconnect the machinery and equipment being tested for insulation resistance as there is a possibility of voltages being induced in apparatus under test or lines to which it is connected (because of proximity to energized high voltage equipment).

Use required PPEs such as rubber gloves etc. when connecting the wire leads to test the apparatus for performing the insulation resistance test.

Some ohmmeter may be provided with a voltage scale to ensure the line to be tested does not have any voltage for insulation testing.

You might also like to read:

- 10 Electrical Jobs Marine Engineers Must Know On Board Ships

- 10 Ways to Achieve Energy Efficiency in Ship’s Electrical System

- Electrical Propulsion System in Ships

- Single Phasing in Electrical Motors: Causes, Effects, and Protection Methods

- How to Minimize the Risks of an Electrical Shock on a Ship?

Disclaimer : The information contained in this website is for general information purposes only. While we endeavour to keep the information up to date and correct, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the website or the information, products, services, or related graphics contained on the website for any purpose. Any reliance you place on such information is therefore strictly at your own risk.

In no event will we be liable for any loss or damage including without limitation, indirect or consequential loss or damage, or any loss or damage whatsoever arising from loss of data or profits arising out of, or in connection with, the use of this website.

Do you have info to share with us ? Suggest a correction

Daily Maritime News, Straight To Your Inbox

Sign Up To Get Daily Newsletters

Join over 60k+ people who read our daily newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

About Author

An ardent sailor and a techie, Anish Wankhede has voyaged on a number of ships as a marine engineer officer. He loves multitasking, networking, and troubleshooting. He is the one behind the unique creativity and aesthetics at Marine Insight.

Read More Articles By This Author >

BE THE FIRST TO COMMENT

12 comments.

we check IR test with voltage as per ohm law current is there so who we handle current

But which voltage on reducing Ac are dc not output

What’s the minimum resistance that a certain equipment is considered grounded.

in what electrical degree connected to current coil and pressure coil in megger?

Hi, have you got a tutorial for megger OTS 100AF?

@Virgil: As of now, we do not have it.

Insulation Testers are a very powerful tool. @mecoinst

These equipment are very suitable for use on ships, but in my country Iran is very expensive. I suggest that other brands be used alongside this brand to reduce overall costs.not bad see the following site for other equipment:

Megger is a combination of ?

@Vijay: Ohm meter and generator

What happened if we apply Meggar in live electrical circuit?

Leave a Reply

Your email address will not be published. Required fields are marked *

Subscribe to Marine Insight Daily Newsletter

" * " indicates required fields

Marine Engineering

Marine Engine Air Compressor Marine Boiler Oily Water Separator Marine Electrical Ship Generator Ship Stabilizer

Nautical Science

Mooring Bridge Watchkeeping Ship Manoeuvring Nautical Charts Anchoring Nautical Equipment Shipboard Guidelines

Explore

Free Maritime eBooks Premium Maritime eBooks Marine Safety Financial Planning Marine Careers Maritime Law Ship Dry Dock

Shipping News Maritime Reports Videos Maritime Piracy Offshore Safety Of Life At Sea (SOLAS) MARPOL

Log in or Sign up

You are using an out of date browser. It may not display this or other websites correctly. You should upgrade or use an alternative browser .

dikikh.dm New Member

Good morning colleagues, There's a need to carry out the megger test, in particular, to make sure that the insulation of the electrical equipment from the earth (the boat's hull) is good enough. Could somebody advice me if I understand this procedure correctly: 1. Since we have only low voltage equipment onboard (220 and 400V), as I understand I can use the lowest megger check voltage. 2. I switch off the breaker of the equipment I want to check. 3. I connect the positive wire (crocodile) of the megger to the earth (the metal door of the junction box) and the negative one to the phase wire of the equipment. 4. I activate the megger tester, check the reading and repeat it for all phase wires. Is it right? Thanks in advance. Best regards.

K1W1 Senior Member

Google How to megger test my motor and watch a few videos till you understand what megger testing is. Given that you obviously think you have an idea and you are going to test every phase between itself and ground not the other phases and will use a moving hinged door as your earth point I would also suggest you ask someone who knows what they are doing to show you. It will be safer for you and everybody else close by and probably a lot cheaper in the long run.

- No, create an account now.

- Yes, my password is:

- Forgot your password?

Don’t let electrics slide: Megger testing

Megger testing helps keep yacht safety high and expenses low..

The harsh marine environments yachts operate in can cause significant wear and tear on electrical systems. Megger testing is an essential aspect of a yacht’s electrical maintenance. It involves using a specialized piece of equipment known as a Megger tester to apply high voltage at low amperage to test insulation resistance on AC electrical motors and equipment. This helps identify any potential faults or damage that may compromise the safety of the yacht, its crew and guests.

The primary reason for performing Megger testing is to ensure the safety of the yacht and its occupants. Faulty or damaged electrical insulation can cause electric shocks, fires and even explosions. By measuring the insulation resistance of the yacht’s electrical system, it is possible to detect any potential issues before they become hazardous. The Megger test helps to identify insulation breakdowns, which can be repaired before they cause any serious harm.

Yachts, like all vessels, must comply with strict regulations to ensure the safety of passengers and crew. Megger testing is a critical part of this compliance process. Periodic testing will be mandated by class societies, though non-class yachts should also at a minimum have Megger testing performed on critical motors such as generator ends, bow thrusters or steering, fire and bilge pumps. Regular testing ensures that the yacht’s electrical system meets the required standards and can operate safely in all conditions. Failure to comply with electrical regulations can result in fines, legal action against the owner and crew, and even no-sail orders.

While Megger testing may seem like an unnecessary expense, it can save yacht owners a significant amount of money in the long run. By detecting and repairing insulation breakdowns early, the cost of repairs is likely to be lower than if the problem had been left to escalate. Poor electrical insulation can cause stray current leakage that can cause corrosion of the hull plating, piping and running gear. In addition, regular Megger testing can help to extend the life of electrical equipment and reduce the need for expensive replacements.

Faulty or damaged electrical insulation can result in a drop in performance, which can affect the yacht’s safety and capabilities. Periodic testing helps to identify any potential issues that could impact the yacht’s performance and cause significant damage or injury. By addressing these issues early with proactive testing, engineers can ensure that their vessel is operating at its optimal level. This helps to prevent breakdowns and costly repairs that can keep the yacht out of commission for long periods.

Spending money on Megger testing is not as fun as a buying a new waterslide but the benefits far outweigh the cost. Though it may require some convincing of the decision makers who pay the bills, yacht engineers should prioritize Megger testing as part of their overall maintenance program to ensure their vessel operates safely, efficiently, and reliably.

JD Anson has more than 20 years of experience as a chief engineer on superyachts. He is currently project manager at Fine Line Marine Electric in Fort Lauderdale.

Related Posts

Your recent survey regarding drug use in the yachting industry revealed how many different opinions there are regarding this very hot topic. (“Crew see drugs…

It’s great to see that The Triton is putting out a survey on drugs onboard yachts, especially now, with some of the main insurance underwriters…

New inflatable play system aims to ease crew pain.

Welcome To Electric Yacht Services Website

Electric Yacht Services, based in Olbia, Europe, specializes in a comprehensive range of marine electrical services, including thermal imaging surveys, insulation testing, and megger tests for both survey and maintenance needs. The company also offers marine electronics installation for entertainment, surveillance, and navigational systems, alongside control engineering services for repair and integration. Additionally, they provide lighting solutions, from installation to repair of various lighting systems, and HVAC services including flushing and boiler maintenance, ensuring a full suite of support for yacht owners.

Our Services

Electrical and lighting systems

Automation and control systems

Maintenance of gangways and hydraulic accesses

Megger test insulation resistance measurement

Technical assistance and emergency resolution

Port support services

Our Worldwide Services

We provide worldwide services comprehensive electric installation and repair services for all types of yachts and boats, ensuring they operate efficiently and safely. Our skilled technicians are equipped to handle a wide range of electrical systems, from navigation and communication equipment to power management and lighting solutions. Whether it's routine maintenance or emergency repairs, we support your vessel with expertise to keep you on the water and enjoying your maritime adventures.

Yacht services

Stunning yachts, megger test, yacht renovation.

We use cookies to provide you a better user experience on this website. Cookie Policy

- Basic Electrical

- Electrical Laws

- Electrical Tools

- Electrical Formulas & Equations

- Electrical Calculators

- Preventive Maintenance

- Electrical Procedures

- Electrical Projects

- Electrical Notes & Articles

- Electrical How to

- Troubleshooting

- Electrical Symbols

- Excel Tools

- Transformers

- Electric Motors

- Generations

- Transmission

- Distribution

- Measurement

- Control Systems

- Electrical Safety

- Electrical Interview

- Electrical MCQ

- Instrumentation & Control

- Renewable Energy

- Electrical Vehicles

- Submit Articles

- Freelance Job

- Privacy Policy

Step-by-Step Procedure: Megger Testing for Transformer Insulation Resistance

The most basic and popular test for determining the strength of transformer insulation is the insulation resistance (IR) measurement. In addition to identifying any major internal defects in the transformer (such as the failure to remove the temporary transportation mounting on the live portion of the tap-changer part), this test also discloses the quality of the insulation, or the degree of dryness of the paper insulation.

Test Equipment

Meggers, available in 500 V, 1000 V, 2500 V, and 5000 V ratings, are used to assess insulation resistance. 2.5 kV megger is required for transformer windings with voltage ratings of 430V, 500V, 430V and above, 1000V megger, and 11 kV and above. It is preferred to use a 5 kV motorized or digital megger for measuring the IR values of EHV transformers.

Testing Procedures

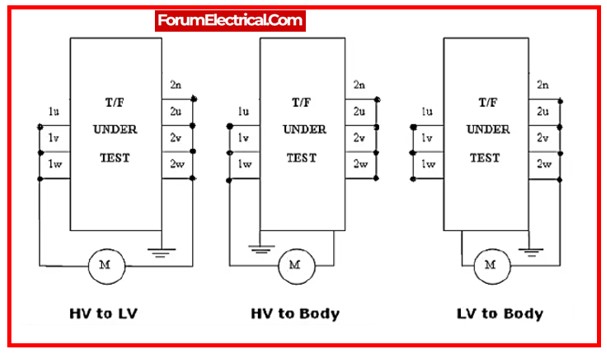

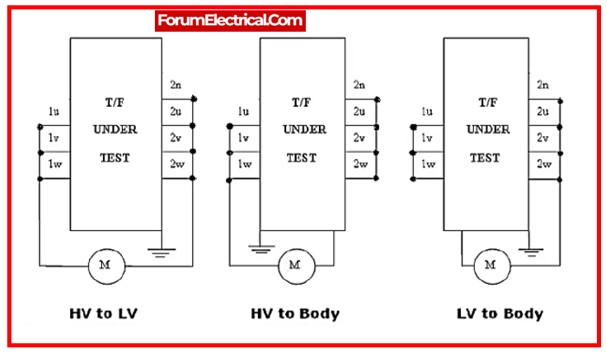

IR measurements must be obtained across the windings collectively (with all of the windings connected together) & the earthed tank (earth), as well as between each winding & the tank, with the remainder of the windings earthed.

Before collecting measurements, unplug the neutral from the earth.

The table below shows IR measurement combinations for

- Auto-Transformer,

- Three-Winding Transformer, and

- Shunt Reactor.

| HV to Earth | HV+IV +LV to Earth | HV+IV to Earth | HV to Earth |

| HV to LV | HV+IV to LV | HV+IV to LV | – |

| LV to Earth | HV+LV to IV | LV to Earth | – |

HV- High voltage windings

IV-Intermediate voltage windings

LV-Low voltage windings

1). HV Windings to Earth

- Connect the Megger’s line terminal (5000V) to the Transformer’s HV winding.

- Connect the Megger’s Earth terminal to the earth pin provided at the electrical equipment.

- Turn ON the Megger.

- Record the readings (they need to be in MΩ).

2). LV Windings to Earth

- Connect the Megger’s line terminal (500V) to the Transformer’s LV winding.

- Connect the Megger’s Earth terminal to the earth pin provided at the electrical equipment.

- Turn ON the Megger.

- Make a note of the readings (they need to be in MΩ).

3). HV Windings to LV Windings

- Connect the Megger’s line terminal (5000V) to one of the Transformer’s windings.

- Connect the Megger’s Earth terminal to the Transformer’s other winding.

Minimum Requirement

- Minimum 200 MΩ for below 6.6 KV class for 1 minute

- Minimum 400 MΩ between 6.6KV and 11KV classes for 1 minute

- Minimum 500 MΩ up to 33KV class for 1 minute

- Minimum 600 MΩ up to 132KV class for 1 minute

- Minimum 650 MΩ up to 220KV class for 1 minute

Core Insulation Check (2500V Megger)

| Value Of Insulation For 60 Seconds |

Connection Diagram

Measurement Table

Temperature = 0 C

| HV to Earth | |||||

| HV to LV | |||||

| LV to Earth |

DAI – Dielectric absorption coefficient (or) index

PI – Polarization Index

Precautions

1. Before testing, the temperature must be documented.

2. Testing cables should not have any joints.

3. Test leads must not come into contact with any live parts.

4. Earth the megger body (if a separate terminal is available).

5. Clean the surface/terminals.

6. IR Preferably, measurements should be taken in dry, sunny conditions.

7. Never connect energized equipment to the test set.

8. The ground terminal should be connected first & then disconnected.

9. After high voltage testing, test terminals should be grounded before any staff touch them.

10. Test leads must be adequately screened and shielded.

RELATED ARTICLES MORE FROM AUTHOR

Transformer oil bdv (breakdown voltage) testing procedure, condition monitoring of transformer, auto transformer: definition, working principle, and diagrammatic representation.

- Marine Engineering

Yacht Services

- Yacht Surveys

- Yacht Electrician

Megger Testing

- Marina Electrical Services

- Industrial Electrical

- Commercial Electrical

- Residential Building Electrical

- LED Lighting

- Industrial Lighting

- Electric Vehicle Charging Stations

- Sales & Parts

- Service Request

- Sales Request

- Privacy Policy

- Terms & Conditions

- RH Marine Group

Tess Electrical LLC has been a leading provider of yacht maintenance, repairs, and upgrade services in Fort Lauderdale for more than 35 years.

Full Range Of Yacht Services

For nearly four decades, Tess has been the most trusted Fort Lauderdale yacht service provider. We put our expertise to work for each of our clients, and we’ve developed a reputation for going the extra mile to meet your needs and timelines. We offer a full range of services for yachts and megayachts typically ranging from 120 feet. Our team is available for service, analysis, and any other work when you need us including nights and weekends. Contact our experienced sales and support team to schedule a survey for your yacht.

Megger testing, or insulation resistance testing, tests how well your electrical systems insulation can resist electrical current flow. As a yacht spends time exposed to the elements, the insulation in your electrical system begins to age and erode which impacts the performance of the insulation. A Megger test applies a test current between the conductors and the chassis of the equipment for about 1 minute. Once we establish a base reading, we then perform readings over a regular interval to compare how the insulation resistance changes over time.

Load Analysis

We also offer comprehensive load analysis testing services to yachts and megayachts. Load analysis testing analyzes the power of your electrical distribution system. It looks to ensure that your yacht's electrical system is not experiencing any overloads and is properly balanced. With this test, we evaluate the voltage, current flow, and power consumption to assess the power factor of a ship. Once we've finished our analysis, we compile a comprehensive report for the client's records.

Fault Finding

Your yacht's electrical system is composed of power, lights, alarms, monitors, switches, fuses, relays, and much more. The more complex your yacht's electrical system is, the more potential there is for something to be faulty. We start by identifying and analyzing all of the components in your electrical system by using your wiring diagram. Electrical problems can occur due to a variety of reasons including loose connections, bad fuses, faulty relays, or any number of other reasons. We use the latest tools and technology to test amperage, voltage, resistance, and more.

Schedule Your Yacht Service Today

If you're considering yacht services and would like to have one of our experienced yacht electricians or electrical engineers take a look at your vessel, give us a call today. One of our experienced support team members will be able to give you more information about the types of tests and analysis we can run and schedule a time for someone to come to you.

We are a Marine Electrical Service Company servicing mostly in the Large Mega Yacht Industry and Marine Land Installations (marinas, resorts, apartments, docks, etc). We have mobile Technicians who cover the tri county area (Broward, Palm Beach and Dade) in their fleet of vehicles.

- Marine Electrical

- Land Division

- ShipServ Ship Supply

Our Services

- Fluorescent To LED Conversion

- All Land Services

- All Marine Services

Sales & Support

- Sales Request Form

Our Location

Tess Electrical LLC

Shipbuilding and Offshore Knowledge – The Continuing Professional Development Program

MEGGER/RESISTANCE TEST

Megger test is the test that evaluate the insulation resistance quality.

Insulation starts to age as soon as it’s made. As it ages, its insulating performance deteriorates. Any harsh installation environments, especially those with temperature extremes and/or chemical contamination, accelerates this process. This deterioration can result in dangerous conditions in power reliability and personnel safety .

As such, it’s important to identify this deterioration quickly so that corrective steps can be taken. One of the simplest tests and its required test instrument are not universally understood. To help eliminate this lack of understanding, let’s discuss in detail Insulation Resistance (IR) testing and the Megohmmeter or Megger test.

Insulation testing components

Let’s approach the subject by component.

The Megohmmeter

First, the megohmmeter’s output is much higher than that of a multimeter. Voltages of 100, 250, 500, 1,000, 2500, 5,000, and even 10,000V are used .

|

|

|

| Up to 100V | 100V and 250V |

| 440V to 550V | 500V and 1,000V |

| 2,400V | 1,000V to 2,000V and higher |

| 4,160V and above | 1,000V to 5,000V or higher |

The most common voltages are 500V and 1,000V. Higher voltages are used to stress an insulation to a greater degree and thus obtain more accurate results.

Second, the range of a megohmmeter is in megohms , as its name implies, instead of ohms as in a multimeter.

Third, a megohmmeter has a relatively high internal resistance, making the instrument l ess hazardous to use in spite of the higher voltages.

Testing connections

A megohmmeter usually is equipped with three terminals. The “ LINE ” (or “ L “) terminal is the so-called “ hot ” terminal and is connected to the conductor whose insulation resistance you are measuring.

Remember: insulation testers should never be connected to energized lines or equipment when operated in any of the Insulation Test or Resistance Test modes.

The “ EARTH ” (or “ E “) terminal is connected to the other side of the insulation, the ground conductor .

The “ GUARD ” (or “ G “) terminal provides a return circuit that bypasses the meter. For example, if you are measuring a circuit having a current that you do not want to include, you interact that part of the circuit to the “GUARD” terminal.

Note that Resistance Insulation is temperature sensitive . When the temperature goes up, Resistance Insulation (IR) goes down, and vice versa. A common rule of thumb is that IR changes by a factor of two for each 10°C change.

For example, suppose we obtained an IR reading of 100 megohms with an insulation temperature of 30°C. The corrected IR (at 20°C) would be 100 megohms times 2, or 200 megohms.

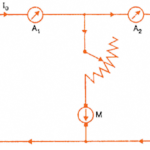

For ship piping system, as below captures extracted from BV, ABS rule:

Share this:

- Click to share on Twitter (Opens in new window)

- Click to share on Facebook (Opens in new window)

2 thoughts on “ MEGGER/RESISTANCE TEST ”

- Pingback: Hazardous Areas Classification – AMARINE

- Pingback: Essential Knowledge of Modern Shipbuilding Industry – AMARINE

Leave a comment Cancel reply

- Already have a WordPress.com account? Log in now.

- Subscribe Subscribed

- Copy shortlink

- Report this content

- View post in Reader

- Manage subscriptions

- Collapse this bar

Insulation Resistance Test (IR Test) or Megger Test

Insulation Resistance or IR Test is carried out by maintenance engineers to ensure the healthiness of the overall insulation system of electrical equipment.

It reflects the presence or absence of harmful contamination, dirt, moisture, and gross degradation.

IR value will be usually high (several hundred Megaohms) for a dry insulation system. Maintenance engineers use this parameter as an index of dryness of the insulation system.

The test measurement values are affected by variables such as temperature, humidity, test voltage, and size of the transformer.

This test should be conducted before and after repair or when maintenance is performed. The test data should be recorded for future comparative purposes. The test values should be normalized to 20°C for comparison purposes.

Insulation resistance test is conducted in most of the substation equipment is high and medium voltage substations.

Recommended Minimum Insulation Resistance for Transformer Winding

The procedure of IR Test:

- First, disconnect all the line and neutral terminals of the transformer.

- Megger leads to be connected to LV and HV bushing studs to measure Insulation Resistance IR value in between the LV and HV windings.

- Megger leads to be connected to HV bushing studs and transformer tank earth point to measure Insulation Resistance IR value in between the HV windings and earth.

- Megger leads to be connected to LV bushing studs and transformer tank earth point to measure Insulation Resistance IR value in between the LV windings and earth.

Insulation Resistance values are taken between the windings collectively as because all the windings on the HV side are internally connected together to form either star or delta. Also, all the windings on the LV side are internally connected together to form either star or delta.

Related: Tests and Tag Courses

Measurements are to be taken as follows :

- HV-IV to LV,

- HV-IV to E,

Related Articles

How does a robotic arm in a production plant repeat exactly the same movements over…

Synchronous motors are not self-starting. Some additional devices should be used to start the motor.…

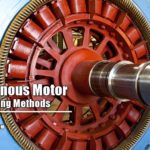

A current transformer is an instrument transformer in which the current ratio is within the…

Swinburne’s test is the simplest indirect method of testing dc machines. In this method, the…

All electrical installations and equipment comply with insulation resistance specifications so they can operate safely. Whether…

This article covers transformer impedance testing, one of the acceptances tests for new transformers, and…

Comments are closed.

Insulation Resistance Testing – Megger Testing

Written by Mark on April 24, 2019 in Megger Testing .

Last update on Aug. 20, 2023 .

Insulation resistance testing is a non-destructive test procedure. The test measures the insulation resistance between the phases and/or between phase and ground. It is commonly used in the industry for acceptance testing prior to energizing the cable and for maintenance testing programs. General Testing Information • For single conductor non-shielded cable on a reel, insulation resistance testing cannot be performed due to the fact that low voltage single conductors do not have a grounding conductor, shield or ground plane. • For other cable on a reel, insulation resistance testing can be performed provided the sealing caps are removed. The procedure to test these cables is outlined below. • NOTE: It is important to remove sealing caps from both ends of the cable to be tested. Residue inside the sealing cap can be conductive and lead to false readings.

Comments are closed.

What is Megger Test?

In this post, we will see the concept of the Megger Test in electrical engineering.

An electrical wire consists of a conductor and insulator. Basically, if you see a wire, the internal metal strap is the conductor and the outer rubber coating covering the conductor is the insulation. It is because of this insulation that we are able to touch a live wire (not the metal strap).

Insulation is a measure of resistance . The higher the resistance, the higher the insulation provided. Over a course of time, due to outside weather, rust and dust, etc. the rubber coating insulator starts to fade or cut away.

If the insulator is cut in a large amount and a large amount of conductor is exposed, then there are chances of spark or a major accident. This is because wires always run in a bunch of pairs, and any conductor short link with another conductor can create a spark or fire due to a short circuit.

So, it is important to check the insulation of a wire. This test is done by the Megger test . A Megger test is done by an insulation tester resistance meter to verify the electrical insulation of a wire.

Megger Test

A Megger meter is also called a Mega-ohm meter . This is because the unit of the meter is in Mega-Ohms. From a small wire used at home to large wires used in transformers, the resistance is checked by the Megger test.

Apart from resistance checking, it is also used to check the open circuit and short circuit of motor windings and electrical wires.

The meter comes in two types – electronic and manual . So, what is the difference between the two? Well, let us first understand how the meter works. The meter is an internal DC voltage producer.

The output DC voltage is given to the wires to be checked. When the voltage passes through them, the meter checks the resistance of the wires connected.

So, basically, an electronic meter is the one that has a battery and the voltage is produced automatically by pressing a test button. A manual meter is one that has a hand lever and the lever needs to be rotated to produce the voltage.

It is not guaranteed for sure that you will get the exact area of the problem or the exact amount of resistance leakage, but you get a very approximate value of the resistance of the wires.

Suppose you are conducting a Megger test of a transformer wire set . For that, you first need to disconnect the supply voltage given to the transformer (HV and LV). Then, the meter is connected between these two wires and you get the resistance value between the phase supply wires. Then the meter is connected between HV and earth point; and then LV and earth point to get the resistance value between phase and ground. This verifies the electrical insulation fully with respect to any potential.

The voltage levels depend on the equipment or wire you are testing. The higher the equipment or wire rating, the higher will be the voltage applied. This fool-proofs the insulation information of the wire and assures the user regarding that.

A current limiting resistor is connected in series to protect damage in case of low resistance of the circuit. A very good resistance value means a large value of Ohms or infinite value. A bad resistance value means a small amount of Ohms .

Many safety precautions need to be followed when doing this test; just due to a large amount of voltage applied. The first and utmost importance is that you should not touch the leads or wires in any case when it is tested. Before doing this test, de-energize or discharge the circuit completely.

Megger test is a very old method of checking insulation. Nowadays, many new modern techniques have come. But this measure is tried and tested, and always gives very good results.

If you liked this article, then please subscribe to our YouTube Channel for Instrumentation, Electrical, PLC, and SCADA video tutorials.

You can also follow us on Facebook and Twitter to receive daily updates.

- What is Electrical Busbar?

- Motor Control Center

- What is Electrical Slip Ring?

- High-Speed Counters in PLC

- Searching Tag number in PLC

Recommended Articles

Difference Between MPCB and MCCB

Effects of Long Distance Cables between VFD and Motor

Circuit Breaker Testing – Routine Tests of Circuit Breakers

Difference between Stepper Motor and DC Motor

Electrical Engineering Documents – Engineers Questions

Electrical Feeder Automation in Smart Grid

What is a Buchholz Relay? Working Principle

Differences between Watts and Volt Amps

What is a Submersible Pump? Principle Advantages Disadvantages

What is Electrical Busbar? Types, Advantages, Disadvantages

1 thought on “What is Megger Test?”

Thank you Very much,this piesce have nice infotmation.

Leave a Comment Cancel reply

More articles.

Transformer Testing – Routine Tests of Transformers

What is an Intelligent Motor Control Center? – IMCC

Why do we need to Control the Motion using VFD drives?

Electrical Drawings

Difference Between Flame Resistant and Flame Retardant Cables

What is Switchgear and Electrical Substation?

Single Phase versus Three Phase Power

Transformers Coolers Weld Joints Oil Oozes Were Eye Sores

Difference between Single-phase and Three-phase Power

Difference Between Normal Inverter and Solar Inverter

MEGGER TEST

Megger test.

Our marine electricians specialize in measuring insulation resistance in marine electrical systems, enabling swift and accurate fault diagnosis. By utilizing advanced testing techniques, they can identify potential issues before they escalate, ensuring the safety and reliability of your vessel's electrical systems. With their expertise, we provide the necessary solutions to maintain optimal performance and compliance with marine safety standards.

.jpeg)

A megger test, sometimes referred to as insulation resistance testing, is performed on your yacht's wiring system to identify any issues that may be causing electrical malfunctions, fires, or short circuits. A current is run through the yacht's electrical system to detect electrical leakage in wires and to find the electrical insulation level in any electrically powered item, including transformers, motors, and cables. Mega ohms are used to measure the test findings.

The electromagnetic attraction theory underlies the operation of Megger tests. A current-carrying coil receives force when it is exposed to a magnetic field. This force produces torque, which is subsequently utilized to deflect the device's reading point.

Request a Visit

Megger testing is used to confirm the general state of a yacht or other commercial vessel's electrical insulation. You may quickly find out through insulation resistance testing whether dust particles and general environmental wear and tear have caused your yacht or commercial vessel's insulation resistance to deteriorate.

One of the main advantages of using Megger testing is the ability to find any current leaks. If these current leaks are not fixed, they may harm your yacht's machinery and other electrical circuits, making it impossible for the vessel to operate as intended.

Visit request

We use cookies to provide you a better user experience on this website. Cookie Policy

- Yacht Charter

- Yacht Refit and Repair

- Yacht Building

MANAGEMENT OF REFIT AND REPAIR

Turkey's Refit Expertise

We set standards in yacht refit and repair as Turkey's leading yacht building firm. We have the courage to lead the superyacht refit industry in Turkey, taking skills and expertise to any project, no matter how basic or complicated. We help captains, operators, and owners of superyachts prepare and conduct refit and repair projects. Our main goal on every job we handle is to make the yacht owners happy.

The customer will have a lot of say on how and where the refit takes place, relying on the accuracy and attention to detail that has made us a reference Refit & Repair business in the market, fulfilling the owner's specifications on time and on budget.

Our staff are on-site, providing our customers with our content of support.

From the beginning, we assign a dedicated Project Manager to each yacht so that we can prepare and handle the appropriate resources in the timeliest and productive manner possible. The project manager becomes the first point of contact, ensuring that your goals are clearly communicated within the organization and that progress is tracked and published on a daily basis. With comprehensive know-how, technical assistance is given from head office, which can advise on all aspects of yacht refit, from structural architecture to finishing details. Interacts with key organizations and has experience working to follow both Flag, State, and Class regulations.

We invest in our human capital by training and developing talented employees who share a core goal of shared inspiration and teamwork. In order to better repair yachts, we keep our facilities up to date.

HIGH-END REFIT & REPAIR SOLUTIONS MADE IN TURKEY

At Ada Yacht, you will be involved in every step of the yacht's growth. The first step is to decide on a style for your yacht, such as classic, urban, futuristic, or traditional. This directs our course, but you remain in charge of everything from the measurements and materials to the collection of technologies and one-of-a-kind solutions. We'll work together to make your dream yacht a reality, one move at a time.

Our company has the expertise, craftsmanship, and resources to custom-build this yacht to your exact specifications. This is what you can depend on. Your yacht will be refitted with the highest attention to detail thanks to our full control over the refit process. We use only the finest fabrics and follow the highest expectations for this exceptional yacht. It is up to you to determine how the yacht will look in the end.

The several yachts that have found a new identity at our facilities have a long tale of accomplishment and milestones to tell, where hospitality, organization, infrastructure, and attention to detail are absolute "musts" in our philosophy. Our company oversees each project by organizing highly skilled experts capable of effectively realizing any kind of action and ensuring functions of rare excellence, based on their vast expertise and operations on hundreds of yachts. Our company has always assured accuracy, punctuality, and seriousness thanks to the existence of a highly technological system, competences, engineering know-how, and professional artisans capable of handling yachts of all sizes, and represents the location where your own yacht's rebirth plan becomes a reality.

WORKS IN TECHNICAL ENGINEERING

From simple repairs to highly complicated big modifications, Ada Yacht offers high-end solutions for any part of yacht refits. We have the expert craftsmen and organizational skills to produce a project that runs like clockwork, no matter how basic or seemingly ambitious your needs are.

If you need minor repairs, part refit/refurbishment, or cabin furnishings, we have the expertise and equipment to complete these tasks with a wide range of yacht styles. You can effectively integrate the introduction of new features in your cabin with repair and/or maintenance work that would otherwise be needed, reducing overall downtime. This guarantees not just the protection but also the value of your yacht.

Our mechanics, as well as our spare parts supply, are top-notch. Interior and exterior construction, architecture, supply, refit, and maintenance are among the services we provide.

Engines, electrical, and hydraulic equipment, as well as painting, polishing, and interior touch-ups, are all part of the yacht's pre-season upkeep.

Regular and scheduled yacht maintenance increases the comfort of the owner and guests on board as well as the yacht's performance in terms of expense.

From an organizational standpoint, we concentrate on the smallest specifics, but let us not forget that what we are looking for is the first experience that will make the visitors feel at ease.

When our clients entrust their yachts to us, they should be assured that they will receive them in outstanding condition. We have tailored service and a wide range of specialties all under one roof and only a short distance apart.

We have the following operational capabilities as a full-service refit yard:

Project Management: Members of our talented project management team are committed to completing the project on time and on budget, and they often go above and beyond to fulfill client needs. Planning, quotes, contracts, invoicing, sourcing, and quality management are all part of the process. With our high capacity to respond to any condition with versatility, our project managers have successfully completed hundreds of tasks, ranging from small repairs to comprehensive overhauls. The project is completed efficiently on schedule and on budget thanks to careful cooperation between teams, external suppliers, and the yacht team.

Our technical office provides clients with naval architecture and engineering experience at any level of the project. From interior and exterior architecture to structural improvements, stability and weight tests, class surveys, and technical papers, there is everything for everybody. Many classification organizations with which we have close partnerships and expertise.

Painting and Refinishing: Our Refit & Repair facilities have complete operating power and are housed in a fully fitted technical marina with painting facilities with monitored atmospheric conditions, including heating, ventilation, and emission treatment systems, temperature and humidity control, overspray recovery and filtration systems, and lighting systems for painting works.

From primer to top coat refinishing, we will have a complete in-house operation devoted to high quality, accredited, and assured yacht paint projects. Professional coating testers take measurements with equipment that is accredited to meet international paint finishing requirements and comes with a written warranty. The Gloss Unit (GU) is 90, and the Depth of Image (DOI) is 90.

Everyone's first experience of the yacht is stern to in a marina berth or at anchorage in a busy harbor. So if you need absolute exterior fairing or a metallic paint job, you can trust that we will appreciate and exceed your highest standards. Fairing, top-coating, antifouling, blasting, varnishing, refinishing, paint shed & tent are only a few of the services available. Within and outside the hull, technology and expertise of surface planning and treatment. For yacht painting and finishing, we have the most precise methodology available. The conventional way of yacht finishing is still in the hands of artisans, despite the fact that new technology has no limits. Corrosion management and security are among the coating services available.

Antifouling: Our team is knowledgeable about antifouling use, both spray and roll on, and will recommend the right option for your needs. Many clients are now aware of the advantages of airless spray application, which ensures even coverage and improved results by applying more paint throughout the process. The choice to use a spray application helps us to reach a cleaner finish, which saves fuel by allowing the yacht to glide more easily across the water.

We've established a close friendship with Awlgrip, International, Jotun, and Boero technical members over the years to ensure that we get the best results with their help anytime we need it. Our staff is also skilled in the use of Propspeed and Pellerclean materials to keep propellers and shafts clean from the first day.

Wood and Carpentry: Beautiful carpentry has a significant impact on the overall appearance and feel of expert craftsmen for each job. Teak decking, interior woodwork, and outside furniture, our talented artisans have a strong appreciation for such a rare and natural material. They are experts in a wide variety of fabrics, techniques, and technology, including teak, veneers, parquetry, and composites, as well as high-quality woods and lacquers, and everything from masts and spars to custom chairs, interiors, and joinery. The raw wood is shaped into a fine artisan's piece by dedicated and skilled hands, and the final product is guaranteed to satisfy. With many years of experience as artisans in this area, we offer committed craftsmanship.

Our design and decor specialists appreciate the demands of the superyacht industry for flawless finishes and top-of-the-line fabrics. As experts in the area, our illustrious team will provide guidance and assistance to the yacht crew and owners in achieving the finest quality finishes in the vessel.

We have an unrivaled local and multinational network of vendors on site, from carpentry and soft furnishings to lighting and electronics, to complement our experience. Many of our clients' visions can be fulfilled by combining the attention to detail needed for projects ranging from minor changes to full interior overhauls with access to a wide variety of fabrics, products, artisans, and artists.

Interior and exterior yacht refurbishment, including internal modifications and system addition or upgrade. Upholstery, embroidery, leather, fixtures, marble, and furniture’s are only a few examples.

Fiberglass Repairs and Constructions: Carbon fiber, epoxy, GRP, polyester, vacuum-bagging, and high-tech cores are used in repairs and constructions.

Equipment and Systems: We appreciate the operating principles of all yacht machinery and we've been on some of the most complicated yachts. We have good working ties with the world's leading manufacturers and will still have a fitting solution for your yacht systems as well as more cost-effective alternatives. Electrics, Electronics, Hydraulics, Refrigeration, Engines, Generators, Shafts, Propellers, Rudders, Stabilizers, and custom refrigeration and electrical systems at all stages ABT-TRAC stabilizer systems, as well as Parker, HRO, Sea Recovery, Village Marin, and Idromar water maker systems, can be serviced by us.

Electrical Work: With a sure air of experience, we conduct every possible research process, providing "in-house" services, spares, and megger checks. The required qualifications for classification societies include generator load monitoring and insulation testing. Our electrical department will provide you with the latest, most up-to-date guidance on everything from personalized A/C panels to Zero Speed Stabilizers and yacht control systems to ensure a future-proof installation on your yacht. Engines, pumps, electrical systems, and electronics need qualified services, repairs, and new installations. Onan and Kohler Power generators and Mastervolt, Victron Energy electrical system modules, and Cantalupi Lighting systems are all serviced by us.

Mechanical Engineering/Machinery: We are able to fulfill all of the yacht industry's mechanical maintenance and conversion needs. Our services include a professionally trained technical staff, a machine shop, as well as the required equipment and manpower to perform field service on specialized subjects. Rudders, tanks, deck equipment, gyro and fin stabilizers, thrusters, and anode repair are all things that need to be replaced.

Auxiliary / Propulsion: Repowering, overhauling, servicing, and repairing all types of equipment. Engine and gearbox repairs, as well as generator maintenance.

Shaft & Props: Work on shaft alignment and production, as well as balance, maintenance, bearing, and coupling work. Remove the shaft, test it, and pitch and repair the propellers.

Hydraulics: Hydraulic parts are crucial for a wide variety of equipment on board, and engineers who work with low-performance stabilizing systems, gangways that don't surpass adequately, or cranes that wreck a jet ski ride can find them painful. To obtain a satisfactory outcome, diagnosis becomes critical, and our specialist hands know how to work with hydraulic parts, how to patch them, and when to replace or overhaul them.

Metal works: Metalwork specifications will range from steel to aluminum, pipework to artwork. Our eye for detail, which encourages personalized designs to ensure that the metal features are appreciated by even the most discerning visitors, is complemented by class trained welders and plate or pipe bending machines capable of producing all metal equipments.

Plan, fabrication, and modification of yacht metal fittings are also available from an experienced team. Metal works are a vital aspect of our projects and we focus on complicated modifications and renovations, such as extensions affecting the overall construction of the yacht. We only work with trained professionals. Class certified structural repairs and upgrades, additions, complete re-builds, or furniture and part design and fabrication.

Our artisans have not only retained ancient customs, but have also created these techniques to create authentic and one-of-a-kind custom-made masterpieces. All structural work is done with the permission of classification societies. Our experience building yachts gives us a great perspective on mixing modern and traditional techniques, and we've made significant improvements in the performance, cost effectiveness, and accuracy of our methods over the years.

We are one of the leading designers and producers of marine deck devices such as awnings, staircases, railings, stanchions, and yacht entry structures, as well as specialty mooring equipment construction in stainless steel.

Welding: Our team of welders is well-versed in all forms of welding, providing high-grade finishes that follow ISO standards in any situation. The hull and decks are cut and replaced as required, while the aluminum superstructure and pilot houses are designed with great precision to prevent the often difficult threat of distortion in the softer alloy. For aluminum and steel, we have class certified welders.

Piping: Any form of piping aboard presents a significant challenge to both designers and manufacturers. We design and fabricate all types of pipes in steel, stainless steel, aluminum, and copper nickel that blend in with the yacht while preventing the common pitfalls of pipe work. When it comes to concrete, polypropylene, PVC, or stainless steel installations, planning a piping upgrade requires a lot of experience.

Rigging repairs and upgrades, mast construction, sail production and repairs, and lifting keels repairs can all be completed with specialist experience.

Hull Thickness Gauging, steel replacement, pipe and valve work, overboard hull valves, Megger checks, and NDT tests are all part of the classification repairs (liquid penetrant testing, x-ray, ultrasonic testing, magnetic particle inspection, vacuum tests).

We recognize that a satisfied crew is an effective crew, so as part of our concierge-level support services, we will manage short and long-term accommodations, schedule transfers and transports, assist with medical needs, provide translating services, and assist with crew admin duties such as permits when required, reservations, outings, and social gatherings. Yacht owners and crews will take advantage of Istanbul hotels, restaurants, and tourist attractions thanks to our location. Our concierge department is at the full discretion of our clients to support and assist them with scheduling and organizing travel and lodging, whether for a short stay or a longer refitting sojourn. Istanbul is the city with rich in culture, tradition, and leisure, with nearby attractions as well as outstanding high-level food for the finest crew and owner hosting.

Our mission is to establish long-term partnerships with our customers, which can only be accomplished by establishing faith. Trust that we will deliver on quality, price, and timeliness, as well as a favorable customer experience for the lifetime of the project in order to attract repeat business.

Advertisement

Supported by

Italian Authorities Open Manslaughter Investigation in Yacht Disaster

A prosecutor involved in the inquiry into the sinking said it was “plausible” that crimes were committed during the accident.

- Share full article

By Emma Bubola and Jeffrey Gettleman

Reporting from Termini Imerese, Sicily

Italian authorities said on Saturday that they had opened a manslaughter investigation into the sinking of the Bayesian luxury yacht, but that they had not yet zeroed in on any potential suspects.

The sleek, $40 million sailing boat went down fast in a storm off Sicily’s coast on Monday morning, killing Michael Lynch, a British tech billionaire; his teenage daughter, Hannah; four of his friends; and one member of the crew. The captain escaped on a lifeboat with 14 others.

On Saturday, Ambrogio Cartosio, the prosecutor in charge of the case, said at a news conference that it was “plausible” crimes were committed during the accident.

“There could be responsibilities of the captain only,” he said. “There could be responsibilities of the whole crew. There could be responsibilities of the boat makers. Or there could be responsibilities of those who were in charge of surveilling the boat.”

Here is what the authorities said on Saturday:

It will be difficult to determine the cause of the sinking until the yacht is brought to the surface and inspected, which could take weeks.

Five bodies were found in the same cabin.

The yacht sank at an angle, with the stern — where the heavy engine is situated — having gone down first.

The captain and the crew, who have been holed up in a Sicilian hotel with other survivors, are allowed to leave Italy. But prosecutors said that they still want to ask them more questions.

The authorities did not perform alcohol or drug tests on the captain or the crew.

The authorities would not comment on whether hatches on the deck had been left open, which would have allowed water to pour in during the yacht’s sinking.

In addition to possible manslaughter charges, the authorities are also investigating the possibility of a negligently caused shipwreck, a crime that carries up to several years in prison upon conviction.

Investigators said they were focusing on why the 184-foot-long Bayesian, which was built in 2008, went down so quickly, especially when other yachts nearby weathered the storm.

Executives at the company that built the boat have said there is nothing faulty with the design of the yacht and have tried to shift the blame to the crew.

At the news conference on Saturday, the authorities were asked why the captain, James Cutfield, an experienced sailor, left the sinking boat while some passengers were still on board.

“The investigations are also focusing on this,” said Raffaele Cammarano, another prosecutor. But he added that the witnesses they had spoken to said that “the event was really, really sudden.”

Some people who were along the Sicilian coast at the time of the sinking described seeing waterspouts, which are vicious funnels of water and wind that sweep across a body of water during thunderstorms. But on Saturday, Italian authorities said they believed it was more likely that a downburst occurred at the time of the accident.

A downburst is a blast of powerful wind that comes surging down from the sky during thunderstorms. The Italian authorities said that extreme weather was “one of the main elements” of their investigation, but added that they were still at the early stages of their inquiry and that they did not want to “play the probability game.”

The rescuers found the bodies of five passengers in one cabin, which was on the left side of yacht. The yacht was found lying on its right side at the bottom of a bay, in about 160 feet of water. The authorities said the passengers who died were most likely trying to flee to the higher side of the boat and were probably sleeping when the accident happened.

The authorities said that they were not certain whether a black box existed and that the hull was still being searched.

Mr. Cartosio would not comment directly on the actions of the crew, but said that it would be “even more painful” if “the sinking was caused by behaviors that were not perfectly in order with the responsibilities that each person must have in the management of navigation.”

But he added that “this is just, in fact, the beginning of an inquiry.”

Emma Bubola is a Times reporter based in Rome. More about Emma Bubola

Jeffrey Gettleman is an international correspondent based in London covering global events. He has worked for The Times for more than 20 years. More about Jeffrey Gettleman

IMAGES

VIDEO

COMMENTS

What Is Megger Testing? A megger test, also known as insulation resistance testing, is run on the wiring system of your yacht and helps to determine any problems in the wiring that can lead to electrical failures, fires, or shorts. To measure electrical leakage in a wire, a current is passed through the yacht's electrical system to determine ...

Procedure To tests the Insulation. Test the megger before use, whether it gives INFINITY value when not connected, and ZERO when the two terminals are connected together and the handle is rotated. To do the test you ensure the cable is disconnected from any devices (megger normally work on 500v, 1000v testers for higher voltage testing).

The readings are logged down, and the graph is plotted, and the trend of insulation resistance is checked. If the reading is reduced to a megger value, then the windings have to be checked and cleaned, and the readings are to be retaken. A separate Electric Power Insulation Resistance Test log book is provided to the ship.

A test volt of 500V D.C is suitable for testing ship's equipment operating at 440V A.C. Test voltage of 1000V to 5000V is used onboard for high voltage system onboard. The current-carrying coil (deflecting coil) is connected in series and carries the current taken by the circuit under test.

2. I switch off the breaker of the equipment I want to check. 3. I connect the positive wire (crocodile) of the megger to the earth (the metal door of the junction box) and the negative one to the phase wire of the equipment. 4. I activate the megger tester, check the reading and repeat it for all phase wires.

Figure 4-Typical record of insulation resistance of a mill motor. Curve A shows test values as measured; Curve B shows same values corrected to 20°C (see page 22), giving a definite downward trend toward an unsafe condition. Reverse side of card (at right) is used to record the test data. Figure 3-Typical scale on the Megger insulation tester.

Megger testing is an essential aspect of a yacht's electrical maintenance. It involves using a specialized piece of equipment known as a Megger tester to apply high voltage at low amperage to test insulation resistance on AC electrical motors and equipment.

Apply Test Voltage: Set the megger to the desired test voltage, typically ranging from 500 to 5000 volts, depending on the motor's specifications. Apply the test voltage and allow sufficient time for the readings to stabilize. Record and Analyze Results: Record the insulation resistance value displayed on the megger.

Electric Yacht Service SRLS, based in Olbia, Sardinia, Italy, offers a wide range of services for medium to large yacht owners, operating on a global scale. Their services include installation and maintenance of electrical and lighting systems, megger testing, electric technical assistance, and specialized port services in the Mediterranean.

The Megger insulation tester is a small, portable instrument that gives you a direct reading of insulation resistance in ohms or megohms. For good insulation, the resistance usually reads in the megohm range. However, let's talk now about three basic types of insulation resistance tests using Megger tester: Short-Time or Spot-Reading Test.

Figure 2 - Typical Megger test instrument hook-up to measure insulation resistance. The generator can be hand-cranked or line-operated to develop a high DC voltage which causes a small current through and over surfaces of the insulation being tested (Fig. 2).This current (usually at an applied voltage of 500 volts or more) is measured by the ohmmeter, which has an indicating scale.

8. The ground terminal should be connected first & then disconnected. 9. After high voltage testing, test terminals should be grounded before any staff touch them. 10. Test leads must be adequately screened and shielded. This post assist to find a detailed Megger transformer insulation resistance testing guidelines.

As a yacht spends time exposed to the elements, the insulation in your electrical system begins to age and erode which impacts the performance of the insulation. A Megger test applies a test current between the conductors and the chassis of the equipment for about 1 minute.

Megger test is the test that evaluate the insulation resistance quality. Insulation starts to age as soon as it's made. As it ages, its insulating performance deteriorates. Any harsh installation environments, especially those with temperature extremes and/or chemical contamination, accelerates this process. This deterioration can result in dangerous conditions in power reliability and ...

Insulation Resistance or IR Test is carried out by maintenance engineers to ensure the healthiness of the overall insulation system of electrical equipment. It reflects the presence or absence of harmful contamination, dirt, moisture, and gross degradation. IR value will be usually high (several hundred Megaohms) for a dry insulation system.

Written by Mark on April 24, 2019 in Megger Testing. Last update on Aug. 20, 2023. Purpose: Insulation resistance testing is a non-destructive test procedure. The test measures the insulation resistance between the phases and/or between phase and ground. It is commonly used in the industry for acceptance testing prior to energizing the cable ...

A Megger meter is also called a Mega-ohm meter. This is because the unit of the meter is in Mega-Ohms. From a small wire used at home to large wires used in transformers, the resistance is checked by the Megger test. Apart from resistance checking, it is also used to check the open circuit and short circuit of motor windings and electrical ...

The MIT515, MIT525, MIT1025, and MIT1525 insulation resistance testers are compact, light 5 to 15 kV units for the diagnostic testing and maintenance of high voltage electrical equipment. They are ideal for original equipment manufacturers (OEMs) and industrial companies. The MIT series has a full suite of test modes as well as on-board memory ...

Megger Test. Our marine electricians specialize in measuring insulation resistance in marine electrical systems, enabling swift and accurate fault diagnosis. By utilizing advanced testing techniques, they can identify potential issues before they escalate, ensuring the safety and reliability of your vessel's electrical systems.

Your yacht will be refitted with the highest attention to detail thanks to our full control over the refit process. ... : With a sure air of experience, we conduct every possible research process, providing "in-house" services, spares, and megger checks. The required qualifications for classification societies include generator load monitoring ...

The yacht sank at an angle, with the stern — where the heavy engine is situated — having gone down first. The captain and the crew, who have been holed up in a Sicilian hotel with other ...

Freakishly, just days before the yacht sank Mr Lynch's co-defendant, Stephen Chamberlain, also died after being hit by a car in Britain. That Mr Lynch's life has been cut short, too, is a ...