How To Build A Wooden Boat [Step By Step]

Building a wooden boat requires the right tools, materials, patience and information.

To build a wooden boat:

- Collect all the materials and tools needed

- Plan the boat layout and design

- Create the center rib & transom

- Create the boat frame

- Add the seat rails & keel strip

- Add the wood planks & seats

- Add epoxy, sand & paint the boat

Building a wooden boat will take approximately 1 month when building a smaller wooden boat under 20 ft. and it will take 2 to 3 months when building a larger wooden boat over 20 ft.

The cost to build a wooden boat will range from $2,500 for a smaller wooden boat to over $3,500 to $5,000 for larger wooden boats. This cost includes all materials and tools needed for the build.

The largest cost when building a wooden boat is the cost of wood. The cheapest cost when building a wooden boat is the boat plans and designs.

The types of wooden boats that can be built include cabin cruisers, sailboats, canoes/kayaks, runabout outboard boats, paddle wheel & runabout inboard boats, novelty boats, houseboats, hydroplanes and race boats.

We include products we think are useful for our readers. If you buy through links on this page, we may earn a small commission.

1. Collect All The Materials & Tools Needed

The first step in building a wooden boat is the collect all the materials and tools need to complete the boat build.

The tools and materials needed to build a wooden boat are:

- Wood : Boat builders will need to get all the wood needed for the build. Popular woods used to build a wooden boat are teak wood, oak and marine plywood for the boat's exterior and pine wood for the boat's interior. Pine is best used for the boat's interior since it has a nice color, finishes well and is light, thereby reducing the overall weight of the boat. The price of marine plywood ranges from $50 to $250 per sheet depending on the thickness and dimensions of the sheet

- Screws : Boat builders will need many batches of screws to screw sections of the boat and wood together. A 100-screw pack will typically cost $10

- Safety gloves & goggles : Boat builders will need safety gloves and goggles when operating tools. This will prevent sawdust and other materials from getting in the eyes. Safety gloves and goggles will cost approximately $25

- Drills & saws : Boat builders will need drills and saws to cut wood and attach it to other wood pieces. Drills and saws will cost approximately $200 to $300

- Wood sanding machine : Boat builders will need a wood sanding machine for sanding wood. A sanding machine will cost approximately $300 to $500

- Epoxy resin : Boat builders can use epoxy resin on the wood material to protect the wood and help keep it waterproof. Epoxy resin costs approximately $70

- Wooden boat paint : Boat builders will need marine wooden paint to paint the wooden boat and protect the wood from the elements. Marine paint will cost approximately $200

- Boat designs & plans : Building a boat will require the boat builder to work from a boat plan. Boat builders can pick up over 500 boat plans for approximately $50

- Varnish : Varnish will add protection and shine to the boat's interior wooden surfaces. Varnish will cost approximately $60

2. Plan The Boat Layout & Design

The second step in building a wooden boat is to plan the boat layout and design.

A boat builder will need boat designs, dimensions, and plans to build the exact wooden boat they want.

Boat builders can access 518 boat plans with 40 boat construction videos. This will provide the exact dimensions to build the majority of recreational wooden boats.

Finding the right boat plans and designs should take 20 minutes to do.

3. Create The Center Rib & Transom

The third step in building a wooden boat is to create the center rib and transom.

To create the center rib & transom:

- Glue the hardwood floorboards together to create the transom

- Sandwich the transom in between two flat pieces of wood or metal and then clamp it tight to make sure that the transom is flat. Use some kitchen wrap to make sure that the two pieces of wood do not get glued to the transom

- Sand the pieces of wood that will be used for the center rib, glues them and clamp them before you glue them together.

- Once the glue is dry, cut out the keel and chines

Creating the rib and transom will take a boat builder 2 to 3 hours. However, this timeframe will vary massively based on the size of the boat and the boat design.

4. Create The Boat Frame

The fourth step in building a wooden boat is to create the boat frame.

To create the boat frame:

- Follow the boat design : Determine the size, shape, and style of your boat. This will dictate the number and spacing of frames required

- Make a full-size drawing : A full-size drawing will help you to lay out the frames accurately. This can be done using paper, plywood or a computer program.

- Cut the keel and stem : The keel and stem are the backbone of the boat. Cut them to the appropriate size and shape

- Determine the frame spacing : Calculate the distance between each frame based on the size and shape of your boat. This will vary depending on the design chosen

- Cut the frames : Use the full-size drawing to create a template for each frame. Trace the template onto the wood and cut out each frame

- Install the frames : Place each frame in its designated location and secure it to the keel and stem using clamps or screws

- Check the alignment : Ensure that each frame is aligned properly with the keel and stem. Adjust as necessary

- Install the stringers : The stringers are the horizontal members that connect the frames. Install them in the appropriate location and secure them to the frames

- Install the planking : The planking is the outer layer of the boat. Install it over the frames and stringers, securing it with screws or nails

Creating a frame for the boat will take approximately 3 to 5 hours to complete. However, this timeframe can vary based on the size of the vessel being built.

5. Add The Seat Rails & Keel Strip

The fifth step is to add the seat rails and keel strip. Then sand and patch the area.

To create the seat rails:

- Determine the location and size of the seat rails : This will depend on the design of your boat and the type of seat you plan to install

- Measure and cut the seat rails : Use a saw to cut the rails to the appropriate length. Ensure that they fit snugly into the boat

- Sand the edges of the seat rails : Use sandpaper to smooth the edges of the seat rails

- Install the seat rails : Secure the rails in place using screws or bolts making sure they are level and well-supported

To create the keel strip:

- Determine the length of the keel strip : Measure the length of the keel and cut the keel strip to match

- Sand the surface of the keel : Use sandpaper to roughen the surface of the keel. This will help the adhesive to bond more effectively

- Apply the adhesive : Apply a marine-grade adhesive to the keel strip making sure to spread it evenly

- Install the keel strip : Press the keel strip firmly onto the keel ensuring that it is centered and well-aligned

Creating the keel strip and seat rails will take approximately 1 to 2 days to complete. This will vary based on experience and the size and design of the boat being built.

6. Add The Wood Planks & Seats

The sixth step in building a wooden boat is to add wooden planks and seats.

To add wooden planks:

- Prepare the planks : Cut the planks to the appropriate size and shape for your boat. If necessary, steam or soak the planks to make them more pliable and easier to work with

- Apply glue to the frames and keel : Apply a marine-grade adhesive to the frames and keel where the planks will be installed

- Install the planks : Begin at the bottom of the boat and work your way up. Place each plank onto the adhesive and secure it to the frames using clamps or screws

- Repeat the process : Continue adding planks until the entire boat is covered. Be sure to sand each plank before installing the next one to ensure a smooth and even surface

- Finish the planks : Once all of the planks are installed, sand the entire surface of the boat to smooth out any rough spots. Finish the planks with paint, varnish, or another protective coating.

To add the seats to the wooden boat:

- Determine the location of the seats : Decide where you want to install the seats and mark the locations on the boat

- Cut the seat supports : Cut pieces of wood to the appropriate size to serve as the supports for the seats

- Install the seat supports : Secure the supports to the frames using screws or bolts. Ensure that they are level and well-supported

- Cut the seat planks : Cut the seat planks to the appropriate size and shape. Sand the edges to ensure a smooth surface

- Install the seat planks : Place the seat planks onto the supports and secure them using screws or bolts. Be sure to leave enough space for cushions or other seat padding

- Finish the seats : Sand the surface of the seats to smooth out any rough spots. Finish the seats with paint, varnish or another protective coating

Adding wooden planks and seats to the boat will take 2 to 3 days to complete. This timeframe will vary based on the size and design of the wooden vessel.

7. Add Epoxy, Sand & Paint The Boat

The seventh step of building a wooden boat is the add epoxy, sand and paint the boat.

After the wooden boat has been constructed, adding epoxy, sanding, and painting it are important steps to protect the wood and provide a finished look.

Here are the general steps for adding epoxy, sanding, and painting a wooden boat:

- Prepare the boat : Before adding epoxy, ensure that the boat is completely dry and free of any dust or debris. Cover any areas that you don't want to be coated with epoxy

- Mix the epoxy : Follow the manufacturer's instructions to mix the epoxy resin and hardener. Use the recommended ratio of resin to hardener for the best results

- Apply the epoxy : Using a brush, apply the epoxy to the boat's surface. Work in small sections, and apply enough epoxy to cover the surface without it running or dripping.

- Sand the epoxy : After the epoxy has dried, use sandpaper to sand the surface smooth. Start with coarse grit sandpaper and work your way up to a finer grit sandpaper. Be sure to wear a mask and safety glasses to protect yourself from the dust

- Clean the boat : After sanding, wipe down the boat with a clean, damp cloth to remove any dust

- Paint the boat : Apply a marine-grade paint to the boat using a brush or spray gun. Follow the manufacturer's instructions for the best results. Allow the paint to dry completely before applying a second coat

- Sand the painted surface : After the paint has dried, use a fine grit sandpaper to sand the surface of the boat. This will help the next coat of paint to adhere better

- Apply additional coats of paint : Apply additional coats of paint as necessary, sanding between each coat. This will help to build up a smooth, even finish

- Finish the boat : Once the final coat of paint has dried, inspect the boat for any rough spots or imperfections. Sand any areas that need attention, and touch up the paint as needed

Frequently Asked Questions

Below are the most commonly asked questions about building a wooden boat.

What Types Of Wood Are Used To Build A Wooden Boat?

The types of wood used to build a wooden boat are:

- Natural Wood : Natural wood like teak, cedar, oak and tuatara are commonly used to build a wooden boat. They are hard and have natural chemicals that prevent marine animals from interfering with the boat's structure. Oak is the most popular hardwood used to build the wooden boat's exterior like the hull and keel area which are always exposed to the seawater

- Plywood : Most amateur boat builders like to use marine plywood since it is easy to bend into the shapes that they want. It is also considerably cheaper than natural woods

- New Woods : Azobe, Iroko, Mahogany, Okoume Keruing and Merbau are popular new woods used in building wooden boats

The ideal wood is one that will is resistant to rot and will not allow marine wildlife to get inside and destroy the structure. The wood used to build a wooden boat should be Forest Stewardship Council (FSC) certified.

The buoyancy of wood means that it will ride higher in the water.

The abrasion resistance of the wood will vary according to how dense and hard the wood is so typically hardwoods are used to make the exterior of the boat while softwoods are used for the boat's interior.

What Are The Best Types Of Wood To Build A Wooden Boat?

The best types of wood to build a wooden boat are teak wood and marine plywood as it is dense, hard, can handle stress and abuse from seawater, it can naturally bend and it contains natural chemicals that prevent rotting.

What Is The Worst Type Of Wood To Build A Wooden Boat?

The worst type of wood to build a wooden boat is pine wood on the exterior as pine wood will rot very fast. While pine wood is fine to use on a boat's interior, using it for constructing the exterior should be avoided.

What Are The Construction Methods Used To Build A Wooden Boat?

There are 5 main construction methods used to build a wooden boat which are:

- Stitch & Tape : This is the simplest and fastest technique when it comes to building a boat. This construction method employs the use of plywood which is then “stitched” together using epoxy resin or glue and some other complex cuts to form the hull of the boat. You do not need specialized tools when using this method. Duct tape, copper wire and cable ties are popularly used to stitch the plywood together. If the boat is being built for marine waters, then copper wires are the best since they do not corrode easily. Once the boat has been stitched together, a thick layer of epoxy or fiberglass is used to keep water away from the “stitched” areas

- Ply On Frame : This is another popular construction method that begins with the creation of a wooden frame commonly known as “ribs”. The next step is to build frame members which are joined to the ribs through slots. The individual frame members are the keelson which is a frame that runs down the center of the boat, the sheer clams which run at the top of each side of the boat and the chine log which are two frames that run along the bottom of the boat and curve up to join the sides of the hull. The joint is called a chine

- Strip Planking (Carvel) : Strip Planking is a quick method of building a wooden boat since there is not much joining to be done. Narrow strips of wood and placed on forms and due to their narrow nature, they can easily be bent to form the shape of the boat. Once the shape of the boat is attained, the strips are then fastened together using strong epoxy adhesives(no fasters are needed in this technique). This is a method suitable for experienced boat builders and not amateurs. This is because there are several methods of strip planking and it should therefore be left to those who know how to go about it. The method is popularly used to create small vessels such as canoes

- Clinker : This is a technique that uses planks of wood that overlap across the edges. This overlapping joint is called a “land”. Clinker, also called lapstreak, creates a boat that is generally lighter and easy to sail. There is less water being displaced along the sides of the hull, which increases the efficiency when the boat is moving. The use of this technique is also for the experts and not amateurs

- Cold Molding : This is a method that uses two or more layers of wood to create the hull. This is a composite method and the wood is known as veneers. The veneers have different orientations, resulting in a powerful hull similar to one made of fiberglass but are much lighter in weight. The orientation is 45 degrees from the center line of the veneer and is also referred to as the double-diagonal method. Cold molding may simply use the layers of veneers or has basic strip planking layers, followed by the veneers. Cold molding is used to create all types of boats, from small boats to large wooden superyachts. To build a boat, the builder uses different woods to put more density in areas of high stress and makes the low-stress areas such as the bow and stern out of lighter veneers

The most popular construction method used to build a wooden boat is the stick & tape method, also known as the "tack and tape method".

How Do You Waterproof A Wooden Boat When Building It?

To waterproof a wooden boat:

- Prepare the wood for applying waterproof materials : Make sure that there are no loose layers of wood shavings or others finishes by properly sanding the wood on the boat. Start off with a rough sandpaper to remove the loose parts and then use a fine one to give the wood a fine smooth finish

- Apply the sealing compound : Using a brush, apply a marine-grade epoxy sealant. Make sure the coats dry completely before applying a second or third coat of the sealant to the wood

- Let the wood cure : A marine-grade epoxy sealant can take up to 7 days to fully cure. Read the instructions on your specific epoxy sealant for exact timeframes but allow for up to 7 days

Although the wooden boat is now waterproofed, it's important that you periodically remove the boat from the water, typically every 2 months, and inspect the wood to make sure that there are no moisture-laden surfaces.

This way, the wooden boat is not exposed to water and moisture for a long time.

What Are The Benefits Of Building A Wooden Boat?

The benefits of building a wooden boat are:

- It costs less money : Building a wooden boat is 30% to 40% cheaper than buying a wooden boat

- Better customizability : Wooden boats can be designed and built to suit individual preferences and needs allowing for a high degree of customization. This can be especially important for those who plan to use the boat for specific purposes such as fishing or leisure activities

- Aesthetic appeal : Wooden boats are known for their classic and timeless beauty. The natural grain and texture of the wood can give the boat a warm and inviting appearance

- Sense of personal fulfillment : Building a wooden boat can be a challenging and rewarding experience that allows individuals to learn new skills and develop a sense of personal fulfillment

- Ease of repair : Wooden boats can be easier to repair than boats made of other materials. If a section of the boat is damaged, it can often be replaced or repaired without having to replace the entire boat

What Are The Disadvantages Of Building A Wooden Boat?

The disadvantages of building a wooden boat are:

- Vulnerability to water damage : Wood is prone to water damage which can cause rotting and cracking. If not properly maintained, this can lead to boat structural problems and ultimately compromise the safety of the vessel

- Higher maintenance costs : Wooden boats require more maintenance than boats made of other materials. They need to be regularly inspected, sanded, painted, and varnished to prevent water damage and maintain their appearance

- Fire hazard : Wood is a combustible material making wooden boats more susceptible to fires. This can be a safety hazard and increase insurance costs

- Susceptibility to pests : Wooden boats are more susceptible to pests like termites and woodworms which can weaken the structure of the boat and require costly repairs

What Should Be Avoided When Building A Wooden Boat?

When building a wooden boat, avoid:

- Building a boat without a plan : Boat builders should avoid building a wooden boat without following a plan with design drawings and dimensions

- Using poor quality materials : When building a wooden boat, avoid using low-quality materials to construct the boat as this will become problematic when the boat is out on the water

- Not adding a protective coating : When building a wooden boat, avoid not adding a protective coating to the wood and this will leave it exposed to the harsh marine environment

- Rushing the building process : Building a wooden boat takes time and patience. Rushing the process can lead to mistakes, poor craftsmanship, and other problems that can affect the boat's quality and safety

- News & Views

- Boats & Gear

- Lunacy Report

- Techniques & Tactics

WOOD BOAT CONSTRUCTION: Practical and Traditional

HUMANS HAVE BEEN building boats out of wood for many thousands of years. Many assume therefore it must now be obsolete. Wood certainly does not lend itself to mass production the way fiberglass does, though there were a few builders who manufactured wood boats on something like a production basis not long before the advent of glass. Wood does have some distinct virtues. It is light, even compared to modern building materials, and in terms of tensile strength is stronger per pound than common electrical-grade fiberglass. In terms of stiffness, it is stronger per pound than S glass, E-glass, and Kevlar. In terms of its total structural efficiency, it is better than all of these materials, including carbon fiber.

One big problem with wood, however, is that certain lifeforms like to eat it. Various fungi can infest and consume it, causing what is known as dry rot. Marine borers like the Teredo worm, or boring insects like carpenter ants and termites, can also chew their way through a boat pretty quickly. Wood also rots when it gets too wet, is easily ignited, and is soft, with poor abrasion resistance. Structurally, in one important sense, it is deficient in that it is much less dense than other materials and thus takes up a lot of space. A wood hull must normally be much thicker than an equivalent glass hull, and its interior structural parts must also be larger. Indeed, wood cannot be used at all to make certain small parts that carry great loads (such as bolts, tie-rods, and rigging wire) simply because it is too soft and too fat to fit.

Perhaps the biggest advantage wood has over any other material, especially when it comes to building boats, is that it is inherently romantic. For this reason alone, it is likely someone somewhere will always be building wooden cruising boats, and that other people will always be sailing them.

Plank-on-Frame Construction

This is the most traditional method of building a wood boat. The principle is simple, though the details are complex. The fundamental structure of a plank-on-frame vessel is defined by a keel, which is the horizontal backbone of the hull; a more vertical stem, which forms the bow; and a vertical sternpost (plus, in the case of many yachts with long overhangs, a much less vertical horn timber that terminates in the transom), which forms the back of the boat. On deep-keel vessels, especially on sailboats, there is also often what is called deadwood fastened beneath the keel. This forms part of the lateral plane well below the waterline and makes up a good part of what sailors normally call the “keel,” particularly its aft section. The forward section is normally inhabited by a solid casting of metal ballast, preferably lead, that is fastened to the bottom of the boat.

A full-keel plank-on-frame sailboat under construction. You can see both the deadwood and the lead ballast down low (Photo courtesy of Rockport Marine)

Fastened to the spine created by these parts is a series of parallel transverse frames that describe the vessel’s hull form. To help support the hull, lateral stringers are installed inside the frames. The skin of the hull consists of a series of planks fastened to the outside of the frames. These planks may be laid on the frame with their edges slightly overlapping, which is known as clinker, or lapstrake, construction. This is often done with smaller boats, but hardly ever with larger boats, as the many ridges formed where the planks overlap greatly increases wetted surface area. Alternatively, planks can be laid on the frame edge to edge, creating a fair, smooth surface, which is known as carvel construction. To make the hull watertight, the seams between carvel planks must be caulked with long strands of cotton and/or oakum.

Open seams on a carvel hull awaiting caulking. Note the tufts of cotton hanging out where caulking is underway (Photo courtesy of Rockport Marine)

The deck of the boat, meanwhile, is supported by a series of transverse deck beams, the ends of which are fastened to lateral shelves installed along the inside of the hull at the top of the frames. Traditionally, the deck consists of planking fastened to the deck beams with all seams, again, carefully caulked. Another common way to seal decks, often used on yachts, is to cover the planking with painted canvas. These days, however, many wood decks are simply good-quality marine plywood sealed with epoxy.

Even from this abbreviated description it should be clear this is a labor-intensive way to build a boat. Much skill is also required. Just selecting wood to build with is an art, as there are numerous criteria to meet. The best wood should be cut only in winter to minimize the retention of moisture and microorganisms. It should then be air-dried in a climate-controlled environment for as long as possible–many months at a minimum. The lumber should also be carefully milled to produce planks and pieces with the wood grain properly aligned to carry anticipated loads in the boat. Finally, if you’re truly fanatic, all pieces should be hewn to size by hand, rather than ripped with power tools, as traditional hand tools do less damage to the fiber of the wood and make it much less prone to fungal attacks.

The biggest issue is embraced in that single verb “to fasten.” A plank-on-frame boat consists of hundreds of pieces of wood, all of which must be carefully shaped and then bound together by thousands of small metal fasteners. Even if you use the best fasteners (silicon bronze screws and bolts are preferred, though Monel is technically superior) what ultimately limits the strength of a plank-on-frame boat is not the wood it is made from, but the fasteners holding it together.

This weakness manifests itself in various ways. First, because they are made from many different pieces, and in particular because so many plank seams are permanently submerged, plank-on-frame boats are apt to leak. Many are continually taking on water when afloat, and normally the only variable is the rate at which water is coming aboard. Invariably this increases when conditions get worse. I once sailed across the North Atlantic aboard a plank-on-frame schooner–one time we almost sank; the other time we did (though, fortunately, this was in a river on the other side). Prior to the voyage, a friend warned me: “A wood boat is nothing but a collection of leaks loosely organized as a hull.” Nothing in my experience proved him wrong.

Plank-on-frame boats also often have deck leaks. The problem here is that wood in the deck is constantly swelling and shrinking as it gets wet and dries out. If the deck has open seams, all this expanding and contracting is apt to create gaps somewhere. Even with painted canvas covering the seams, or with a solid plywood deck sealed in epoxy, there are again many fasteners securing hardware, each offering a potential route for water intrusion. Other structures sprouting from the deck–deckhouses, hatches, raised gunwales, etc.–also present seams and cracks where they join the deck that water can eventually seep through.

World-famous small-boat cruiser Larry Pardey waters the deck of his boat, Taleisin , to keep the planks swollen tight. That’s his equally famous wife Lin peering out the companionway. Larry is a master boatwright (he built Taleisin himself) and maintains his boats scrupulously

Finally, plank-on-frame boats can be a bear to maintain. All that wood, above the water and below, needs to be either painted or varnished on a regular basis. Leaks must be policed and stanched if possible. Moist areas in the structure must be sought out, constantly monitored for rot, and replaced if the rot gets out of hand. As Bernard Moitessier once put it: “The maintenance of my wooden boats had always confronted me with delicate problems and required real qualifications, for I had to be ‘Doctor of Rot,’ ‘Doctor of Teredos’ and ‘Doctor of Leaks.’ ” Some people enjoy this sort of work and anxiety. Most, however, like Moitessier, would much prefer to just go sailing.

Wood-Epoxy Construction

Plank-on-frame boats still have a strong cult following and a relatively large number of older wooden yachts are sailed and maintained by devoted owners. Some new plank-on-frame yachts are also built from time to time, and a few boatyards–the most prominent are probably Gannon & Benjamin on Martha’s Vineyard and Rockport Marine in Maine–even specialize in this sort of work. But the most exciting wooden boatbuilding these days is done with composite wood-epoxy construction.

The key ingredient is modern epoxy, which is not only a tenacious adhesive, but is also highly elastic and nearly impermeable to water. By sealing and coating every piece of wood in a boat with epoxy, and by using epoxy to help glue these parts together (aided, too, by the judicious use of metal fasteners), it is possible to take full advantage of wood’s excellent structural properties while negating its tendencies to rot and swell and contract when exposed to water. Epoxy also protects the wood from hungry creatures that want to eat it.

Furthermore, a wood-epoxy hull forms a one-piece monocoque structure that cannot leak unless punctured. In most cases, to improve abrasion and impact resistance, the hull and deck are also sheathed in one or more layers of fiberglass cloth. The result is a boat with many of the virtues of fiberglass, with the added benefits of built-in insulation, plus all the fuzzy romantic feelings inspired by a genuine wood finish.

There are many ways to construct a wood-epoxy boat. One could, for example, build a wood-epoxy plank-on-frame vessel, but this would be labor intensive and the boat would be needlessly heavy and thick. In practice, there are three basic approaches–strip-plank construction, sheet plywood construction, and so-called cold-molded construction. Each has many variations, and to some extent different techniques can be combined in a single hull.

In a simple strip-plank hull the frame is an important part of the structure, and the strip planks, which are narrow–with a square section shape, are both attached to the frame and edge-nailed to each other. Boats were often built like this in the traditional manner (and are still built) without being encapsulated in epoxy. In more modern variations, there is more reliance on epoxy, fiberglass sheathing, and internal accommodations structures (including bulkheads) to support the hull, with framing reduced to a minimum. Some of these vessels are essentially fiberglass boats with solid wood cores. Strip-planked wood-epoxy hulls are probably the most common type built today, as they are generally the most cost effective.

Sheet plywood construction is the least common type, at least as far as larger sailboats go. Mostly this technique is used for smaller boats like dinghies, skiffs, and daysailers. The one major exception are Wharram catamarans, which are usually built of plywood, and may or may not be coated in epoxy. In a plywood boat of any size, a substantial amount of framing is needed, but construction otherwise is relatively simple and fast, as large sheets of plywood can be set in place more easily and quickly than many narrow planks. Plywood construction does limit design options. Normally plywood hulls are hard-chined, although lapstrake construction–as seen, for example, in some very interesting Dutch Waarschip designs–can also be employed.

The third major variation, cold-molded construction, is more properly described as diagonal-veneer construction. Here the hull is composed of several layers of thin wood veneers that are laid up on a diagonal bias over light framing or a jig. The layers of veneer are oriented at right angles to each other and are glued together and stapled in place until the epoxy sets up. Often there are one or more layers also oriented laterally at a 45-degree angle to the diagonal layers. By laminating thin sheets of unidirectional veneer atop one another like this, a light monocoque structure that is strong in multiple directions can be created. These cold-molded boats are, generally speaking, the lightest of wood boats, but this method of wood construction is also by far the most labor intensive. The technique is shunned by some, but is favored by those for whom weight reduction is critical. It is also sometimes used in conjunction with strip-planking, with layers of diagonal veneer laminated over a planked hull in place of fiberglass sheathing.

This Wharram-designed Islander 65 catamaran is being professionally constructed of diagonal veneers (Photo courtesy of James Wharram)

The hull of this large cold-molded yacht has diagonal veneers being laid over strip planking (Photo courtesy of Hodgdon Yachts)

The term cold-molded is something of an historical anomaly. The first laminated wood hulls were composed of veneers laid up in female molds and glued together with adhesives that could only cure in an oven. The expression “cold-molded” was born later when it became possible to use adhesives that cure at room temperature. The term is still used to describe diagonal-veneer hulls, but not other types. Technically speaking, any wood-epoxy hull laid up at room temperature can be said to have been cold-molded.

Whatever they are called, wood-epoxy vessels in fact make superb cruising boats. The only problem is that wood-epoxy construction does not lend itself to series production. If you want a new wood-epoxy boat, you must commission its creation as a one-off, and many people with money to burn have done just that. Many modern wood-epoxy boats are based on traditional designs but take full advantage of modern design and construction techniques to minimize weight and maximize performance. Others are full-out modern superyachts measuring over 100 feet in length and a few are flat-out race boats. For example, Bruce Schwab’s very intriguing Open 60 OceanPlanet was a wood-epoxy boat. So, too, was Holger Danske , an early BOC boat designed by Dave Gerr that had a phenomenally low displacement/length ratio of 40. This is one of the lowest D/L ratios ever achieved in an ocean-racing monohull, which gives some idea of just how cutting-edge wood-epoxy can be.

Dave Gerr’s ocean racer Holger Danske , a very light boat built out of wood (Photo courtesy of Gerr Marine)

Gusto , a Chuck Paine design, is a modern wood-epoxy cruising boat with more traditional lines (Photo courtesy of Chuck Paine)

Wood-epoxy boats can also, of course, be found on the used-boat market. Recently built boats are relatively rare and normally command a significant premium, but older boats, some dating back to the early 1970s, are often quite affordable. Be sure to have them carefully surveyed, however, as construction techniques have improved considerably in recent years. As with any older boat, there will likely be problems that need addressing.

Related Posts

COASTAL DELIVERY: From Marblehead MA to Southport CT On a Classic Aage Nielsen Sloop

NICK SKEATES ON WYLO II: The Ultimate Barebones Cruiser and his Ultimate Dirt Simple Boat

I love wood boats and have built my share over the years but one thing that is worth mentioning is that a wood boat behaves differently in the water compared to a fiberglass or boat built of other materials. It is hard to quantify but the motion is ‘softer’.

I bought these plans ( https://sites.google.com/view/boatbuilder/home ) and building started last June 14th and it was ready to launch August 6th . I’ve been building boats since I was 12 years old…a long time ago!…and wish these plans were around, then. Martin Reid is the real deal. His materials are very informative and inspiring…an excellent investment for anyone who is interested in building boats.

@Mark: ahoy sir! good to see you here! very interesting comment. I am very willing to believe that construction materials affect the quality of a boat’s motion. wood especially. another factor most people don’t think of is the position of the ballast. in my experience, the closer the crew is to the ballast, the more comfortable the motion. charlie

You didn’t say anything about stitch and glue construction. I think it’s the only way to go. It’s the way I built the boat of my own design.

The softer motion is due to the bigger moment of inertia the mass of the boat is spread out more. Kinder motion less seasickness seasickness is a major safety factor.

Shop Silicon Bronze Screws

What are the exact things I will need to build this boat? And do you have any suggestions on what kind of wood to make a boat? Thank you!

Hello Robert: Which boat are you referring to??? As to what wood to use, that depends a lot of what construction technique you will employ, but generally hard woods are best.

Hello Charles: First off, Thanks for your reply. The boat I referring is 16′-18′, less than 800 lbs with deck and center console. Do you have any suggestions? Thank you again.

Search for dinghy boat plan

It’s not possible to build a boat, which are bigger than a dinghy, i.e. the type of boats shown in the pictures above, if it has to weight less than 800 lbs.

It seems to me that the large number of dived woodships in the world has one reason. Most of wood boat buildings dont aplay enginering concepts. The few others never proved the right use full time for the project in the sea. Its wrong?

I’m glad you talked that using plank-on frames could offer a durable function for your boat but needs detailed creation. Yesterday, my close friend told me he and his family hoped to find boat-building epoxy products to help them create a durable project boat for their fishing adventures. He asked if I had thoughts on the best buying option. I’m thankful for this informative boat creation article. I’ll tell him they can consult the boat products online store to gather details about their boat products.

I wish I could get in touch with the boat architect, and get a boat construction plan from him

Leave a Reply Cancel Reply

Save my name, email, and website in this browser for the next time I comment.

Please enable the javascript to submit this form

Recent Posts

- BAYESIAN TRAGEDY: An Evil Revenge Plot or Divine Justice???

- MAINTENANCE & SUCH: July 4 Maine Coast Mini-Cruz

- SAILGP 2024 NEW YORK: Lifestyles of the Rich and Famous

- MAPTATTOO NAV TABLET: Heavy-Duty All-Weather Cockpit Plotter

- DEAD GUY: Bill Butler

Recent Comments

- Gweilo on SWAN 48 SALVAGE ATTEMPT: Matt Rutherford Almost Got Ripped Off! (IMHO)

- Alvermann on The Legend of Plumbelly

- Charles Doane on BAYESIAN TRAGEDY: An Evil Revenge Plot or Divine Justice???

- Nick on BAYESIAN TRAGEDY: An Evil Revenge Plot or Divine Justice???

- jim on BAYESIAN TRAGEDY: An Evil Revenge Plot or Divine Justice???

- August 2024

- January 2024

- December 2023

- November 2023

- October 2023

- September 2023

- August 2023

- February 2023

- January 2023

- December 2022

- November 2022

- September 2022

- August 2022

- February 2022

- January 2022

- December 2021

- November 2021

- October 2021

- September 2021

- February 2021

- January 2021

- December 2020

- November 2020

- October 2020

- September 2020

- August 2020

- February 2020

- January 2020

- December 2019

- November 2019

- October 2019

- September 2019

- August 2019

- January 2019

- December 2018

- November 2018

- October 2018

- September 2018

- August 2018

- February 2018

- January 2018

- December 2017

- November 2017

- October 2017

- September 2017

- August 2017

- February 2017

- January 2017

- December 2016

- November 2016

- October 2016

- September 2016

- August 2016

- February 2016

- January 2016

- December 2015

- November 2015

- October 2015

- September 2015

- August 2015

- February 2015

- January 2015

- December 2014

- November 2014

- October 2014

- September 2014

- August 2014

- February 2014

- January 2014

- December 2013

- November 2013

- October 2013

- September 2013

- August 2013

- February 2013

- January 2013

- December 2012

- November 2012

- October 2012

- September 2012

- August 2012

- February 2012

- January 2012

- December 2011

- November 2011

- October 2011

- September 2011

- August 2011

- February 2011

- January 2011

- December 2010

- November 2010

- October 2010

- September 2010

- August 2010

- February 2010

- January 2010

- December 2009

- October 2009

- Boats & Gear

- News & Views

- Techniques & Tactics

- The Lunacy Report

- Uncategorized

- Unsorted comments

WOODEN BOW TIES

How to build a wooden sailboat: a beginner's guide.

Are you interested in building your own sailboat? If so, building a wooden sailboat can be a rewarding and fulfilling experience. Not only will you have a unique vessel to call your own, but you’ll also learn valuable woodworking skills along the way.

To get started, you’ll need to gather the necessary materials and tools. This may include oak plywood, epoxy resin and hardener, thickener, brad nails, masking tape, a pull-saw, and a table saw. Once you have everything you need, you can begin the process of building your sailboat. From creating a jig and frame assembly to making the mast, there are many steps involved in building a wooden sailboat. But with patience and attention to detail, you can create a beautiful and functional vessel that will bring you joy for years to come.

Understanding the Basics of a Wooden Sailboat

If you are interested in building a wooden sailboat, it’s important to understand the basics of how a sailboat is constructed. In this section, we’ll cover the parts of a wooden sailboat and the different types of wooden sailboats.

Parts of a Wooden Sailboat

A wooden sailboat is made up of several parts, each with its own unique function. Here are some of the most important parts:

- Hull : The hull is the main body of the boat. It is the part of the boat that sits in the water and provides buoyancy.

- Keel : The keel is a long, narrow fin that extends down from the bottom of the hull. It helps to keep the boat from capsizing by providing stability.

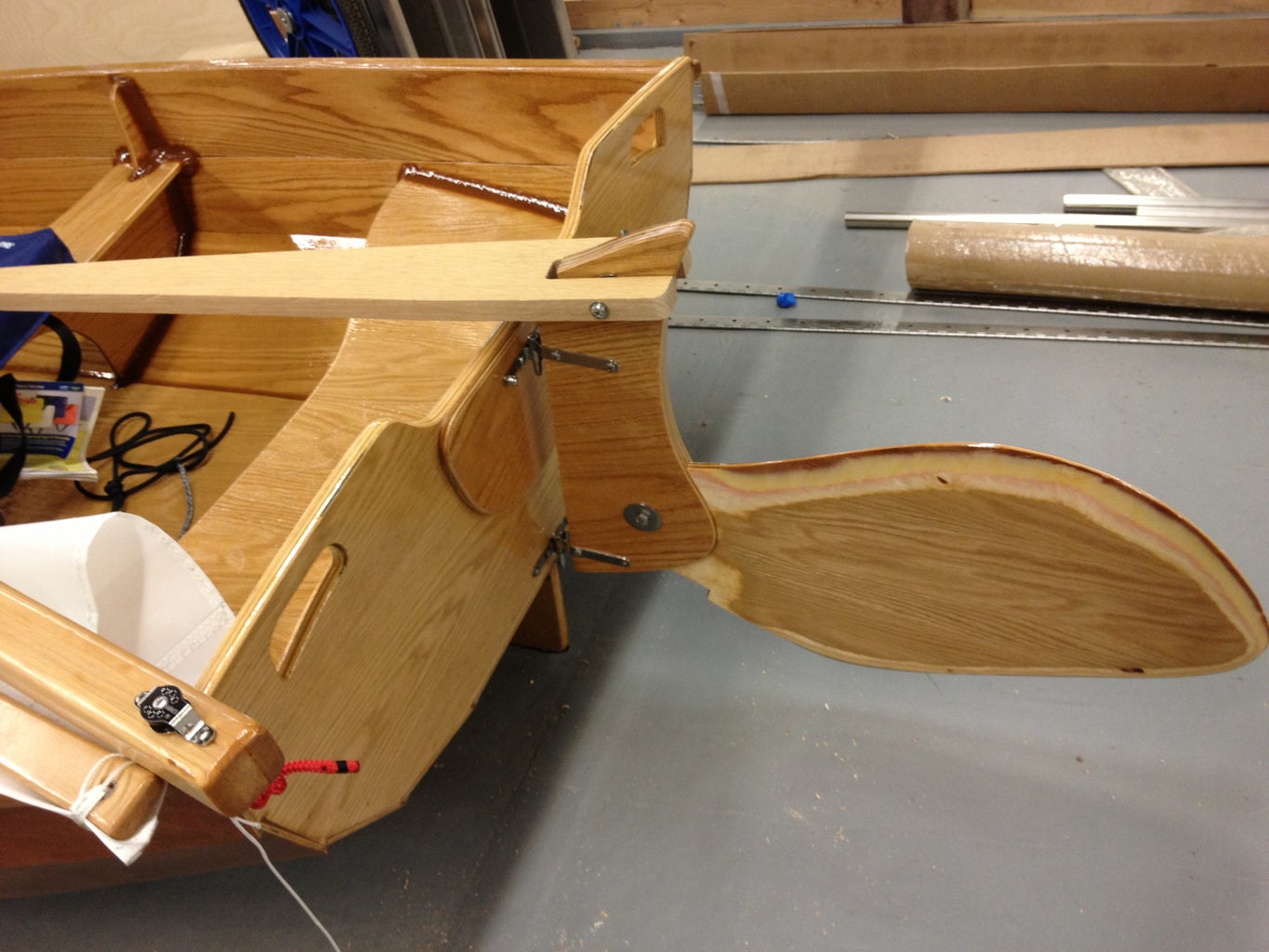

- Rudder : The rudder is a flat piece of wood or metal that is attached to the back of the boat. It helps to steer the boat.

- Mast : The mast is a tall, vertical pole that supports the sails.

- Sails : The sails are large pieces of fabric that are attached to the mast and other parts of the boat. They catch the wind and propel the boat forward.

- Boom : The boom is a horizontal pole that is attached to the bottom of the mast. It helps to control the shape of the sail.

Types of Wooden Sailboats

There are many different types of wooden sailboats, each with its own unique characteristics. Here are some of the most common types:

- Dinghy : A dinghy is a small sailboat that is typically used for recreational sailing or racing.

- Sloop : A sloop is a sailboat with a single mast and a fore-and-aft rig.

- Ketch : A ketch is a sailboat with two masts, with the main mast taller than the mizzen mast.

- Yawl : A yawl is a sailboat with two masts, with the mizzen mast located aft of the rudder post.

When choosing a type of wooden sailboat to build, it’s important to consider your needs and experience level. A dinghy is a good choice for beginners, while a ketch or yawl may be more suitable for experienced sailors.

By understanding the basics of a wooden sailboat and the different types available, you can make an informed decision about which type of boat to build.

Choosing the Right Materials

When building a wooden sailboat, choosing the right materials is crucial to ensure the boat’s durability and performance. In this section, we will discuss the two most important materials you’ll need to choose: wood and sails/rigging materials.

Selecting the Right Wood

Choosing the right type of wood for your sailboat is critical. You want a wood that is strong, lightweight, and resistant to rot and decay. Some of the most popular types of wood used in sailboat building include:

- Cedar: Lightweight and easy to work with, cedar is an excellent choice for planking and decking.

- Mahogany: Strong and durable, mahogany is often used for building frames and keels.

- Oak: A dense and hard wood, oak is commonly used for building frames and planking.

When selecting your wood, make sure it is free of knots, cracks, and other defects that could weaken the boat’s structure. You should also consider the wood’s grain pattern, as this can affect the boat’s strength and appearance.

Choosing Sails and Rigging Materials

The type of sails and rigging materials you choose will depend on the type of sailboat you’re building and your sailing needs. Some of the most common materials used in sail and rigging construction include:

- Dacron: A strong and durable synthetic material, dacron is commonly used for sailcloth.

- Nylon: Lightweight and flexible, nylon is often used for spinnaker sails.

- Stainless Steel: Strong and corrosion-resistant, stainless steel is commonly used for rigging hardware.

When selecting your sails and rigging materials, consider the conditions you’ll be sailing in and the type of sailing you’ll be doing. For example, if you’ll be racing, you may want to choose lightweight sails and rigging materials that will help you achieve maximum speed. On the other hand, if you’ll be cruising, you may want to choose more durable materials that can withstand rougher conditions.

By choosing the right materials for your wooden sailboat, you can ensure that your boat is strong, durable, and performs well on the water.

Designing Your Sailboat

Before you start building your wooden sailboat, you need to design it. This will involve creating a blueprint and determining the size and shape of your boat.

Creating a Blueprint

Creating a blueprint is an essential step in designing your sailboat. It will help you visualize your boat and ensure that you have all the necessary components in place. You can create a blueprint using software such as AutoCAD or SketchUp, or you can draw it by hand.

When creating your blueprint, consider the following:

- The length, width, and height of your boat

- The position of the mast and sails

- The location of the rudder and keel

- The number of cabins and their layout

- The placement of any storage compartments or equipment

Determining the Size and Shape

The size and shape of your sailboat will depend on several factors, including your budget, the type of sailing you plan to do, and the number of people who will be on board.

Consider the following when determining the size and shape of your sailboat:

- The type of sailing you plan to do (coastal cruising, racing, etc.)

- The number of people who will be on board

- The amount of storage space you will need

- The amount of deck space you will need

- Your budget

Once you have determined the size and shape of your sailboat, you can start gathering materials and building your boat.

Building the Hull

When building a wooden sailboat, the hull is the most important part of the boat. It is the main structure that holds everything together and keeps the boat afloat. Building the hull requires cutting and assembling the wooden frame.

Cutting the Wood

To begin building the hull, you will need to cut the wood into the appropriate sizes and shapes. The wood should be cut according to the plans or blueprints that you have created. You can use a saw or a jigsaw to make the cuts.

It is important to use high-quality wood that is free of knots or other defects. The wood should be strong enough to withstand the pressure and weight of the water. Common types of wood used for building a wooden sailboat include cedar, oak, and mahogany.

Assembling the Frame

Once you have cut the wood, you can begin assembling the frame of the hull. The frame is made up of vertical pieces of wood called frames, which hold the shape of the boat. The frames are attached to the keel, which is the main structure that runs down the center of the boat.

To assemble the frame, you will need to use a sawhorse or other support to hold the lumber in place. You can then use screws or bolts to attach the frames to the keel. It is important to ensure that the frames are level and straight.

After the frames are attached to the keel, you can add the planks to the hull. The planks are attached to the frames and keel using screws or nails. It is important to ensure that the planks are properly aligned and spaced.

Once the planks are attached, you can sand and finish the hull to give it a smooth and polished look. This will also help to protect the wood from the elements.

Building the hull of a wooden sailboat requires patience and attention to detail. With the right tools and materials, you can create a strong and beautiful hull that will last for years to come.

Installing the Deck and Cabin

Installing the deck and cabin of your wooden sailboat is a crucial step in the construction process. It not only adds to the aesthetics of your boat but also provides structural support. Here are some tips to help you through the process.

Deck Installation

The deck of your wooden sailboat should be installed after the hull has been completed and before the cabin is built. It is important to ensure that the deck is watertight to prevent any leaks. Here are the steps to follow when installing the deck:

- Cut the deck to fit the hull and sand the edges to ensure a tight fit.

- Apply a layer of epoxy to the hull and deck joint to seal it.

- Secure the deck to the hull using screws or bolts.

- Apply a layer of fiberglass cloth and epoxy to the deck to make it watertight.

- Sand the surface of the deck to prepare it for painting or varnishing.

Cabin Installation

The cabin of your wooden sailboat provides shelter and storage space. It is important to ensure that it is properly installed to prevent any leaks. Here are the steps to follow when installing the cabin:

- Build the cabin on a flat surface using marine-grade plywood.

- Cut the cabin to fit the deck and hull and sand the edges to ensure a tight fit.

- Apply a layer of epoxy to the cabin and deck joint to seal it.

- Secure the cabin to the deck using screws or bolts.

- Apply a layer of fiberglass cloth and epoxy to the cabin to make it watertight.

- Install any windows, hatches, or doors in the cabin.

- Sand the surface of the cabin to prepare it for painting or varnishing.

By following these steps, you can ensure that your wooden sailboat’s deck and cabin are properly installed and watertight. This will not only make your boat look great but also ensure that you have a safe and enjoyable sailing experience.

Setting Up the Mast and Sails

Now that you have built your wooden sailboat, it is time to set up the mast and sails. This process may seem daunting, but with a little patience and attention to detail, you can have your boat ready to sail in no time.

Step 1: Install the Mast

The first step is to install the mast. Depending on the design of your boat, the mast may be a single piece or assembled from multiple sections. Make sure the mast is secured properly and is straight. Use a level to ensure the mast is vertical in both directions.

Step 2: Prepare the Sails

Next, prepare the sails. Make sure the sails are clean and free of any debris or damage. Attach the sail to the mast using the halyard, which is a rope used to raise and lower the sail. Make sure the sail is hoisted all the way to the top of the mast.

Step 3: Attach the Boom

Attach the boom to the mast and secure it with a boom vang, which is a rope used to control the angle of the boom. The boom is the horizontal spar that holds the bottom edge of the sail.

Step 4: Set the Sail

Once the boom is attached, set the sail. Adjust the angle of the boom and the sail to catch the wind and start moving. You can use the main sheet to control the angle of the sail and the boat’s speed.

Step 5: Trim the Sail

Finally, trim the sail to optimize its performance. This involves adjusting the sail’s shape and position to maximize its power and minimize drag. Use the sail controls, such as the cunningham and outhaul, to adjust the sail’s shape. Use the main sheet to control the sail’s position relative to the wind.

Congratulations! You have successfully set up the mast and sails of your wooden sailboat. Now it’s time to hit the water and enjoy the thrill of sailing.

Applying Finishing Touches

When it comes to building a wooden sailboat, applying the finishing touches is a crucial step that can make all the difference in the final product. Here are some tips and tricks to help you get the perfect finish.

Sanding and Finishing

Before you can apply any finish, you need to make sure the surface is smooth and free of imperfections. This means sanding the wood with progressively finer grits of sandpaper until you achieve the desired smoothness. Once you’ve finished sanding, you can apply a wood conditioner to help the wood absorb the finish more evenly.

When it comes to choosing a finish, you have several options. Some popular choices include varnish, paint, and oil. Varnish is a popular choice for wooden boats because it provides a durable, glossy finish that can withstand the harsh marine environment. Paint is another option, but it requires more maintenance than varnish and may not provide as much protection against the elements. Oil is a good choice if you want a more natural look, but it may not provide as much protection as varnish or paint.

Painting and Varnishing

If you decide to go with paint or varnish, there are a few things to keep in mind. First, make sure you apply the finish in a well-ventilated area to avoid inhaling fumes. Second, make sure you apply thin, even coats and allow each coat to dry completely before applying the next. This will help prevent drips and ensure a smooth finish.

When it comes to varnishing, it’s important to use a high-quality brush and work quickly to avoid brush marks. You may also want to consider using a foam brush for hard-to-reach areas. Once you’ve applied the final coat of varnish, you can buff the surface with a soft cloth to achieve a high-gloss finish.

Painting requires a different approach. You’ll need to choose the right type of paint for your boat and make sure you apply it evenly. If you’re painting a large area, you may want to consider using a paint sprayer to achieve a smooth, even finish. Once the paint has dried, you can apply a clear coat to protect the paint and give it a glossy finish.

In conclusion, applying the finishing touches to your wooden sailboat is an important step that requires careful attention to detail. By following these tips and using the right tools and materials, you can achieve a beautiful, long-lasting finish that will protect your boat and make it stand out on the water.

Safety Measures

When building a wooden sailboat, safety should always be your top priority. Here are some safety measures you should take to ensure a safe and successful build.

Installing Safety Equipment

Before you start building, make sure you have all the necessary safety equipment installed in your workshop. This includes fire extinguishers, smoke detectors, and first aid kits. You should also have a clear and unobstructed path to the exit in case of an emergency.

When working with power tools, always wear eye and ear protection, as well as a dust mask to protect your lungs. If you are using chemicals, make sure you are working in a well-ventilated area and wear gloves and a respirator if necessary.

Conducting a Safety Check

Before you start working on your sailboat, conduct a safety check to make sure everything is in order. Check that all tools and equipment are in good working order and that there are no loose or damaged parts. Make sure your work area is clean and free of clutter, and that all cords and cables are properly secured.

When working with wood, be aware of any knots or cracks in the wood that could weaken the structure of your sailboat. Use only high-quality marine-grade wood and be sure to follow the plans carefully to ensure a strong and safe boat.

By following these safety measures, you can ensure that your wooden sailboat build is a safe and enjoyable experience.

Maintaining Your Wooden Sailboat

Congratulations on building your own wooden sailboat! Now that you have a beautiful vessel, it’s important to keep it well-maintained to ensure its longevity and safety on the water.

Regular Maintenance

Regular maintenance is essential to keep your wooden sailboat in top condition. Here are some tips to keep in mind:

- Clean your boat regularly with a mild soap and water to prevent dirt and grime buildup.

- Check for any signs of damage, such as cracks, rot, or loose fittings, and address them promptly.

- Apply a fresh coat of varnish or paint every few years to protect the wood from the elements.

- Keep your boat covered when not in use to protect it from the sun and rain.

Seasonal Maintenance

In addition to regular maintenance, there are also some seasonal tasks that you should perform to keep your wooden sailboat in top condition:

- At the beginning of the season, inspect the hull for any damage or wear and make any necessary repairs.

- Check the rigging and sails to make sure they are in good condition and make any necessary repairs or replacements.

- Before storing your boat for the winter, make sure to properly winterize it to protect it from the cold and moisture.

Additional Tips

Here are some additional tips to keep in mind when maintaining your wooden sailboat:

- Use high-quality marine-grade products when cleaning and maintaining your boat.

- Avoid using harsh chemicals or abrasive materials that can damage the wood.

- Regularly check the bilge for any water buildup and pump it out as needed.

- Keep your boat well-ventilated to prevent moisture buildup and mold growth.

By following these tips, you can keep your wooden sailboat in top condition and enjoy many years of safe and fun sailing.

Leave a Reply Cancel reply

You must be logged in to post a comment.

How to Build a Wood Sailboat

Introduction: How to Build a Wood Sailboat

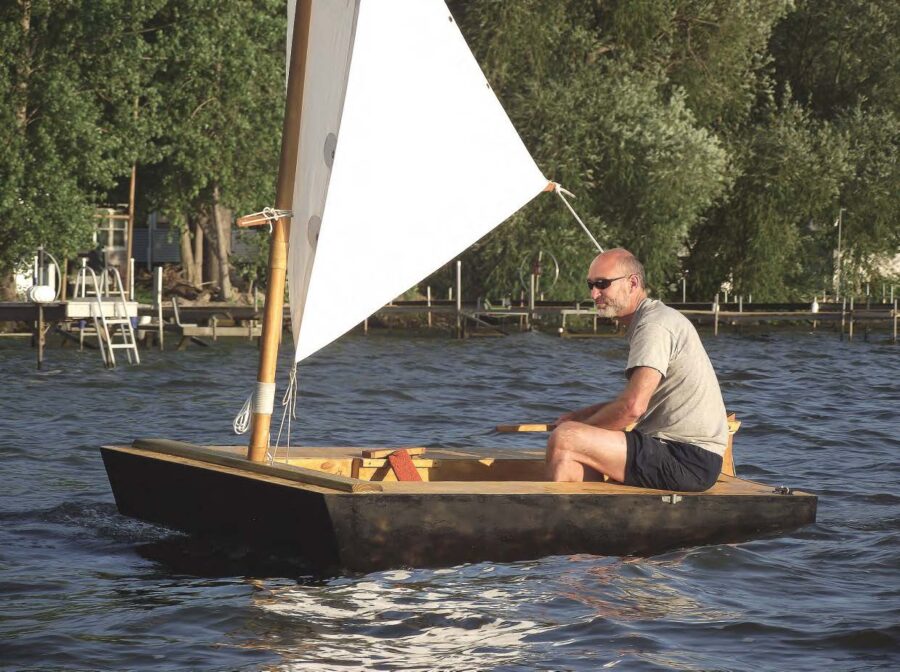

I've been wanting to combine my two favorite hobbies - woodworking and sailing for a long time, so I thought I'd build a boat. It's got classic lines and looks so dazzling in the sunshine that people constantly stop me at the boat ramp to ask me about it. There's something unbelievably rewarding about building something like this from scratch. This is definitely a boat that is much better built than bought . Here's how I did it.

The boat takes about 100 hours to build. I did it over 3 months, working a little bit just about every day and full days when my schedule permitted.

It will take about $1,000 in total to build if you buy everything at full retail cost (not including tools you might need to buy), but you can spread that across the length of the project. For example, you only need to buy one $30 sheet of plywood at a time, take it home, draw out the parts (loft) that fit on just that sheet and cut them out. That will take a couple of hours right there. Some boating supply stores (chandleries) might let you setup an account which might give you a discount if you tell them you're building a boat.

All of the skills needed to build a sailboat can be learned slowly, one step at a time. For example, if you've never fiber-glassed plywood before, just practice on a small piece first to get your confidence up. This was my first boat build, so I did a lot of learn as you go . Not only am I going to show you the right way to successfully build your own sailboat, but I'm going to share with you the mistakes I made along the way to hopefully save you from repeating them.

The end result will be a very attractive little 8 foot long pram, that is easily made out of 4x8 sheets of plywood that is light enough to put in the back of a small pickup truck or roll down to the local lake on the optional dolly. Anything longer would require you to either make a scarf joint (which is a bit tricky) or buy longer sheets of plywood (which is considerably more expensive).

What you will need:

Boat building plans

8 panels of 1/4" oak plywood 4'x8'

Pencil, Sharpie, ruler, tape measure, yard stick, etc.

Long flexible straight edge

Box of 1" brad nails

2 gallons of epoxy resin

1 gallon of epoxy hardener - SLOW

1 quart silica thickener

5 quarts wood flour thickener

1" masking tape

Japanese pull-saw

Table saw (helps, but optional)

Round-over router bit

Flush trim router bit

Palm/random orbital sander

220 sanding discs

Combination square

Drill bit set

Drill bit extension

Basic hand tools

Small diameter wire or zip ties

Wire cutter

12 C-clamps - 3"

Mixing cups, mixing sticks, rubber/nitrile gloves

16' x 60" of 6oz fiberglass cloth

2" plastic spreader

Gallon of waterproof glue

Glue roller

Silicone bronze screws

Stainless steel fasteners

Small blocks

Gudgeon & pintle - dinghy size

Patience - large

Elbow grease - large

For more detailed explanations on each step and more specific info/reviews on the materials and parts used, check out my boat build blog: www.Midnight-Maker.com

Step 1: Cutting Out the Parts...

First, you'll need boat building plans. I purchased some very nice ones from a popular boat building website because I had a specific style in mind to build, a "pram". It's a Norwegian design with lots of buoyancy in the bow and building a pointy boat is a little more difficult. There are a bunch of free boat building plans (search "dinghy") online. Also, I wanted my boat parts to fit in a standard (read cheap) 4'x8' sheet of plywood. It also had to be light enough for me to load/unload/move myself. This boat weighs in at about 70 pounds. When on the custom dolly I built, it's very easy to move from the parking lot to the lake.

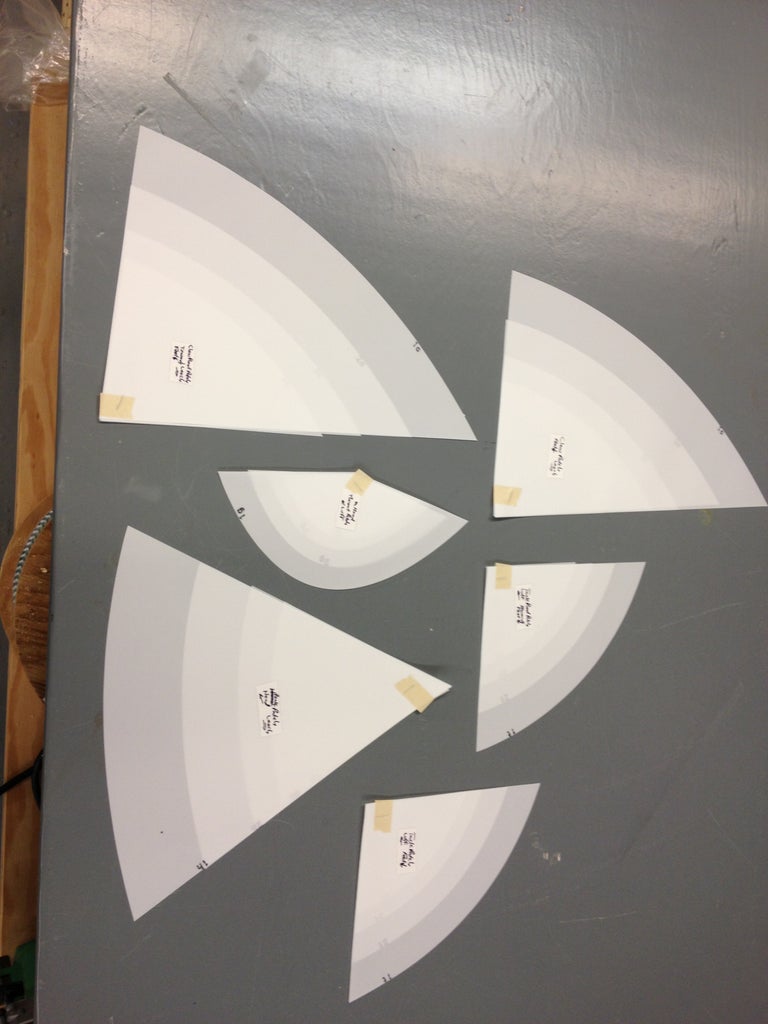

Next, you'll need to draw out the parts of the boat full-sized onto the plywood (lofting). I actually did this step on hardboard/masonite because I wanted to make templates of all the parts in case I ever wanted to build another one.

This step requires you to be very meticulous. Carefully transfer the measurements (offsets). They may or may not look correct because it's very non-intuitive to look at curved boat parts that are laying flat. Some parts actually bend the opposite way you think they should. To make the curves, I nailed a bunch of 1" brads into the panel and used a long, flexible straight edge (yard stick, etc.) bent to follow the curve, then I traced the curve with pencil/Sharpie. Once I removed the brads, I had perfectly smooth curves. Keep in mind that with the side panels that are symmetrical to both sides of the boat, only draw out one version and cut two stacked sheets at a time. This ensures the boat will not be lop-sided. Make sure to immobilize the two sheets together with screws outside of the boat parts or use double-sided tape/clamps, etc. to keep the parts registered properly.

Using a Japanese pull-saw allows you to control the cuts very carefully and it can follow the graceful curves. They cut on the pull stroke which means they're very easy to control. Make sure you leave a bit of your cut line, meaning cut just outside the line. This allows you a bit of a safety margin and you can always sand to the line to sweeten it up. This is where the elbow grease really kicks in. It takes hours to cut out the hull panels by hand, but it's worth it. I tried cutting the first part out with the jigsaw and it wandered all over the place and quickly cut inside the line before I knew it. Also, a jig saw blade can lean to one side which could mean two panels might not be the exact same shape. Using hand tools is a classic way to do woodworking and is a very gratifying process. With hand tools, things happen slow enough for you to be in total control, whereas power tools can quickly do unexpected damage. With the understanding that you're building a classic boat, using hand tools wherever possible is part of the philosophy.

The plans I bought were in metric and called for 6mm (1/4") and 9mm (3/8") plywood, but I wanted to make everything out of 1/4" plywood so the thicker parts in the plans were glued together with two layers of 1/4" (so at 1/2" they were a bit thicker than designed). I actually liked this because it made the boat feel sturdier and of course it was cheaper that way. The trade-off was that the boat would be a bit heavier.

For any of the parts that need to be doubled-up/laminated (e.g. the transoms), now is a good time to do that. Make sure you use "waterproof" glue instead of "weatherproof" glue like I did...

Spread a thin layer of glue over one of the "bad" sides (plywood usually has a good side and a bad side, glue bad sides together so good sides show on both outside faces), making sure it's completely covered (I used a special glue roller), then carefully place the other half on top. Align all of the edges together, then clamp them in place. Now put heavy things carefully on top to press the parts together. The glue should be dry in about 6 hours.

NOTE: It's considerably easier and safer to do any woodworking processes to the parts before you assemble the boat. This way, you can safely clamp pieces to the work bench and cut out handle holes, etc. Since my boat is a "lapstrake" design, I had to route a rabbet (groove located on the edge) carefully on the bottom edge of each side panel. This creates a shoulder for the parts to sit on, positively locating them while you're stitching the panels together. Likewise, the grab handles in the transoms are much easier to cut out before putting the boat together.

Also keep in mind that any mistake will be considerably more painful the further you are along in the build. For example, if I biff cutting out the grab handle holes while they're just loose pieces rather than when they're a permanent part of the boat, it's much easier to recover - just make another transom. If you had to patch a hole in the boat, it would be difficult and possibly never look perfect. No pressure...

Step 2: Assembling the Hull...

Once you have the bottom and sides cut out, you can start to "stitch and glue" the hull together. This is a technique used usually for smaller boats to be able to pull the hull form together without the need to build a frame or mold (which can take almost as long and as much wood as the boat itself).

I built a gauge stick to make sure my holes were perfectly spaced at 4" at 1/2" in from the plywood edge. It was 1" wide so either edge was the required 1/2" from the centerline. I worked my way down one side of each of each mated seam and drilled all those holes at once while the panels could lay flat on the bench. Make sure to use a backer block to prevent tear out on the back side, even with such a small drill bit.

With one mating panel drilled with a 1/16" drill bit, hold the mating panel in it's relative position. I used some spare twine to wrangle my panels into the proper orientation as I was marking them. Make a pencil mark where the mating hole should be, remove the pre-drilled panel and drill the second set of holes 1/2" in from the edge. This makes sure there's enough strength to hold the boat together.

The first pass on the stitches is just to get the hull together structurally. You can always go back and make the stitches fancier/tighter and tweak the position of the panels.

The stitches go from the inside out. Cut 6" lengths of wire and bend them into long, narrow U's that are the width of the distance between the holes. Stick the ends through the holes and carefully twist the tails together on the outside of the hull, making sure not to damage the plywood. If you're using zip ties, then the holes you drill will need to be bigger and you'll have to start on the outside, go in, turn around, then back out, then "zip".

Make sure your panels' rabbet shoulders are resting securely on the mating panel and carefully tighten all the stitches. For my boat, once I had two panels stitched to the bottom panel on each side, it was time to attach the transoms (ends). Once all of the exterior parts are stitched together, you should have something that looks like a boat. It will be a little rickety at this stage, but that's okay.

NOTE: In the photos I took of my build, you'll notice that the transom doublers (reinforcers) aren't in place. That was because I was following the instruction manual, but I think that was a mistake, so I highly recommend laminating (gluing) the doublers to the transoms before you stitch the boat together.

Step 3: Reinforcing the Hull Joints...

Now that the hull is stitched together, flip it over upside down. You'll be surprised at how stiff it is, considering how difficult it was to wrangle all those panels into position. Be careful, there's lots of poky wire ends sticking out all over the place.

I used a technique called "tabbing", meaning I made small, structural tabs from thickened epoxy that fit between the stitches, then I removed the stitches and made one long, larger fillet to connect the hull panels together.

Make sure your panels are perfectly aligned and tightened. I used a nipper to lop off most of the tails so they wouldn't get in the way, but that left very sharp spikes.

Make sure your boat is square. Take diagonal measurements from corner to corner, make sure the boat parts are parallel to each other, etc. because if there's a twist in your boat, the next step will make it permanent, which will affect the boat's performance.

Now mix up a batch of epoxy and silica thickener according to the manufacturer's directions (meaning each type of epoxy has a different resin to hardener ratio) until it's between the consistency of thick ketchup, but runnier than peanut butter (make sure to mix the 2 parts of epoxy together first very well before adding a thickener). Too thick and it won't fill the void, too thin and it'll run down inside the boat. Both are bad. I used a small syringe to inject the mix into the V intersection between the panels and checked underneath/inside to see if there were any runs.

Once the epoxy has partially set, use a glove wet with denatured alcohol to smooth out the "tabs" so they fit inside the V groove and don't extend above the intersection between the panels. This will give you good practice for the seams that will show on the finished boat. Be careful of the wire spikes.

Repeat this process for every seam on the hull. Let it cure overnight.

Once the tabs have cured, carefully remove the stitches. If the wire seems to be epoxied permanently to the hull, heat the wire with a lighter. That will soften the epoxy enough to pull the wire out. Be careful not to scorch the boat (you don't want a Viking funeral). Now repeat the thickened epoxy process for each overlap, except this time each seam will need to be one long, smooth joint. Let it cure overnight. This goes a long way in making the boat hull structural.

Step 4: Fiberglassing the Hull...

Now that you've got a permanent hull shape, it's time to make it waterproof and rugged. Fiberglass and resin over plywood is a tried and true Do It Yourself boat building technique which makes it strong and light.

Mask off the bottom panel and roll out your fiberglass cloth. Smooth the cloth out very carefully so as not to snag or tweak the fibers' orientation. Mix up an unthickened batch of epoxy (it will be the consistency of syrup). Starting at the stern, pour a small puddle of epoxy and spread it out nice and thin. You should be able to squeeze most of the epoxy out of the cloth, leaving only saturated cloth with no dry spots (which will appear white) but the weave should still be showing (meaning no extra epoxy is pooling). You should easily be able to see the wood grain through the cloth now.

Let the epoxy partially cure and using a razor, slice the dry fiberglass cloth away on the taped seam. Then remove the masking tape. Let the epoxy cure overnight.

Flip the hull over and mix up a batch of epoxy that is the consistency of peanut butter. I masked off the joint, but this step is optional, but keep in mind that it will be visible if you plan on finishing the interior bright (varnished wood). It's not as critical if you're painting the interior. With a plastic spreader, carefully make a large radius transition (fillet) between the bottom panel and the first side panel (garboard). Remove the masking tape when the epoxy mixture is partially cured and carefully scrape/wipe any unwanted mixture. It's much easier to remove now than having to sand it all off later. At this point, it's also a good time to fillet the transoms to the sides using 3/4" radius tabs between stitches and 1" finished fillets after you've removed the stitches. Let the fillets cure overnight.

Now, repeat the entire fiberglassing process on the inside. Except instead of just doing the bottom panel, make sure both the bottom and the garboard are fiberglassed. This is basically the waterline of the boat. The fillet should allow the fiberglass cloth to smoothly make the bend between boards. Remove the excess cloth when partially cured and let sit overnight. Some people fiberglass up onto the transom at this stage which will make the boat stronger, but that means you have to have already filleted the transoms to the bottom.

Step 5: Installing Interior Parts...

The bulkheads get stitched in place just like the panels. They will make the already stiff (and much heavier boat) completely structurally sound and push/pull the sides into their final shape. Then make 3/4" "tab" fillets between the stitches to lock them in place, remove the stitches and make long, smooth 1" fillets. The smaller fillets will get covered by the larger fillets. I used two different modified plastic spreaders to do this step. Each spreader was cut with a box knife and filed/sanded into its final shape.

While you're doing the previous steps, if you're in a time crunch, go ahead and build the daggerboard trunk. It's made of numerous parts that are pre-coated with a couple layers of unthickened epoxy, then glued together with silica-thickened epoxy. This makes it strong and waterproof as it will be below the waterline so must be completely waterproof.

The daggerboard trunk is the most important part of the boat, especially if you're making a sailboat version (this boat can easily just be used as a rowboat). Not only does it support the center seat (thwart), but it has to transfer all of the force from the sail to the water and if you run the boat aground, it takes all the shock loading from the daggerboard.

The daggerboard gets filleted into place like everything else. Make sure it's perfectly on the centerline of the boat as that will affect its sailing characteristics.

Next, let's make the daggerboard slot in the center thwart. I set up a straight edge with a spiral upcutting router bit. Make sure to enlarge the slots at the end of the center thwart so that it can fit around the fillets of the center bulkhead. Now is the time to ease the edges of the center thwart because you'll be sitting on it a lot, so it needs to be comfortable. Because it's so thin, I only routed the top edge of the center thwart that shows and just hand sanded the edge underneath (it's very problematic to use a round-over bit on the second side of a thin board). Paint all of the thwarts with three coats of unthickened epoxy, especially the undersides. Once the woodworking is done, the thwart can be epoxied into place with peanut butter (or you can jump to cutting the daggerboard slot in the bottom of the hull). Make sure the thwart fits snugly in place. Drop dollops of peanut butter on the top edges of the center bulkhead and daggerboard case and spread it out evenly (make sure none gets inside the slot to interfere with the daggerboard). Firmly seat the thwart (pun intended) into the goop and weight it down. Let it cure overnight.

While you've making sawdust, cut out the mast hole (partner) in the forward thwart by drilling holes in the four corners (for the square mast we're going to make), then cut out the sides, file it smooth, then round over the top edge with the router.

Any time after the bulkhead thwart fillets have cured, you can seal the airtank chambers. Paint the bottom, sides, inside of the bulkhead and transom up to the level where the thwart will be.

Step 6: Rail & Sailboat Parts...

There are several processes in this boat building instructable that can be done concurrently. While you're waiting for the epoxy on one part to cure, you can be doing woodworking or epoxying another part. This step illustrates that point. While you're waiting for the epoxy on the rub rail (outwale) to cure, you can be fabricating the sailboat accessories (e.g. daggerboard, rudder, tiller, spars, etc.).